Wastewater Treatment Plant Resolves Downtime Issue and Saves Up To $600,000 with AFT Arrow

AFT Arrow™ Case Study

Brown and Caldwell | Aeration System | Water & Wastewater

“The ability to model the entire aeration system once and use it to answer multiple questions regarding

sizing, equipment selection and construction sequencing was critical in allowing the client to make

informed decisions for the long-term viability of the plant.”

-Maren Deal, Brown and Caldwell

PROBLEM

- Blowers experienced surge conditions in hot months

- Growing plant capacity required new construction, but plant must remain operational during implementation

ANALYSIS

- AFT Arrow was used to evaluate existing blower operation

- Model helped inform equipment selection and construction sequencing to maintain operation

SOLUTION

- Reduced blower pressure resolved downtime issues

- Blower capacity increased by the equivalent of 2.5 blowers with no additional capital

Ready to try AFT Impulse?

Problem Explained

Maren Deal, with Brown and Caldwell, was hired to design the reliability and process improvements project at a 64 million gallons per day (240,000 m3/day) wastewater treatment plant. AFT Arrow was used extensively for the design and planning of the upgrades to the plant’s aeration system, as well as for the optimization of the existing operation.

As the largest wastewater treatment plant serving its surrounding area, this plant is the linchpin of the wastewater treatment system providing a backup to other neighboring plants in cases of heavy flows, construction related bypassing, or emergencies. Due to its essential nature, the plant had to remain in operation throughout the upgrade project. Aeration tanks were taken offline in groups to keep the plant operational, demolishing the existing air piping and diffusion equipment to be replaced by the new design.

Tools and Analysis

As the design-build construction process progressed, AFT Arrow models were used to determine in what quantity and order the aeration tanks should be taken offline and replaced. Blower replacements were also considered to meet the air demand of the new aeration tanks as they are constructed.

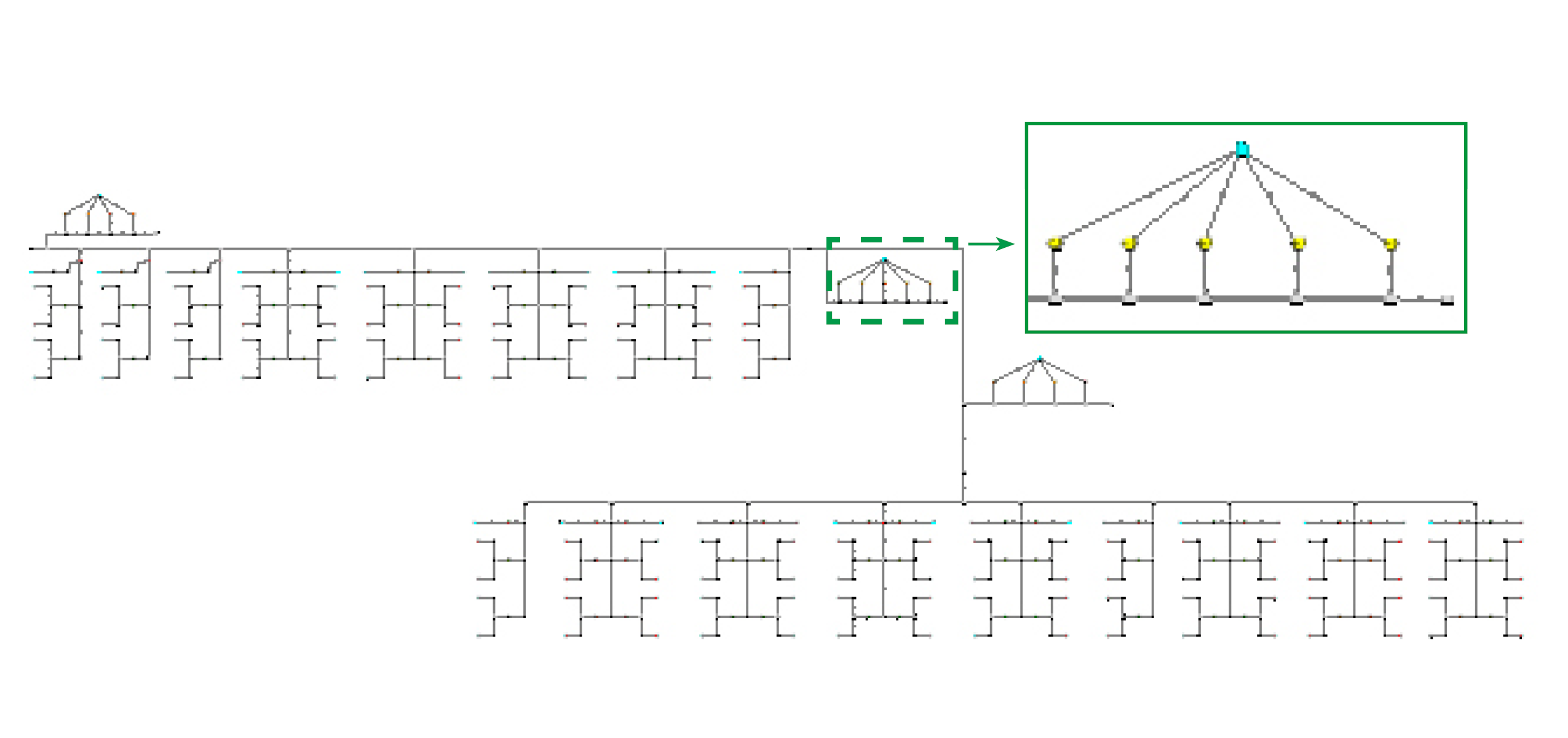

An AFT Arrow model was developed for the entire original aeration system. This model was used to evaluate the existing blower operations at a discharge pressure set point of approximately 8.0 psi (0.55 bar). Using AFT Arrow, Deal was able to determine whether it would be possible to lower the discharge pressure setpoint of the blowers to 7.2 psi (0.50 bar), reducing the risk of surge conditions. The results of the model demonstrated that not only could you decrease the pressure setpoint, but this would also increase the air flow by 30,350 scfm (48,800 Nm3 / hr) which would equate to approximately 2.5 additional blowers (Figure 2).

Solutions & Benefits

Though decreasing the pressure setpoint was originally considered for implementation in conjunction with one of eight other options, the results of the model proved that it would be more than enough to provide the additional capacity needed and reduce the risk of surge conditions occurring in hot weather. Additionally, a cost analysis of the primary options determined that reducing the blower pressure setpoint saved the plant between $200,000 and $600,000 in capital and installation costs compared to the alternatives.

Deal said the ability to model the entire aeration system once and use it to answer multiple questions regarding sizing, equipment selection and construction sequencing was critical in allowing the client to make informed decisions for the long-term viability of the plant. AFT Arrow will continue to be used to evaluate the system with changing information and under different flow and treatment scenarios. Deal said AFT Arrow is a very versatile program and she looks forward to continuing to explore its uses in wastewater treatment.

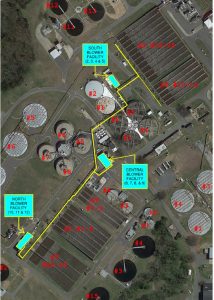

Figure 1: The original aeration system which included

three blower facilities with a total of 11 blowers that

provide air to 28 aeration tanks around the plant.

The yellow lines on the map show the air manifold

connecting all of the air piping and blower facilities.

Figure 2: Workspace view of AFT Arrow model. The results of

the model demonstrated that not only could the blower pressure setpoint be reduced, but this would also increase the air flow by 30,350 scfm (48,800 Nm3/hr) which would equate to approximately 2.5 additional blowers at no cost to the client.