AFT Fathom Used to Identify and Address Slurry Deposition in Polymer Cooling System

AFT Fathom™ Case Study

LyondellBasell | Slurry Deposition | Chemical and Petrochemical

“The original design relied on simplifying assumptions in another hydraulic modeling tool,

the limitations of which were proven after an analysis with AFT Fathom’s SSL module”

– Rajitha Papagari, LyondellBasell

PROBLEM

- Reliability issues in polymer slurry cooling circuit for reactor causing costly downtime to clean

- Solids deposition reduced recirculation rates

- Other approximation method models failed

ANALYSIS

- AFT Fathom modeled settling slurry, indicating polymer deposits which were confirmed during system turnaround

- Pump performance was derated following standard ANSI/HI 2016

SOLUTION

- Modeled modifications to piping improved operation and eliminated need for larger pump, saving $435K in capital costs

- Reduced downtime saved $247K annually

Ready to try AFT Fathom?

Problem Explained

LyondellBasell engineer, Rajitha Papagari, performed a reliability study on a polymer slurry cooling system used to maintain a stable temperature in a reactor, critical to maintaining product quality. This system had several reliability issues leading to downtime and associated maintenance costs to clean the piping. The existing system was unable to meet design requirements, potentially due to solids deposition not considered in the initial design.

Tools & Analysis

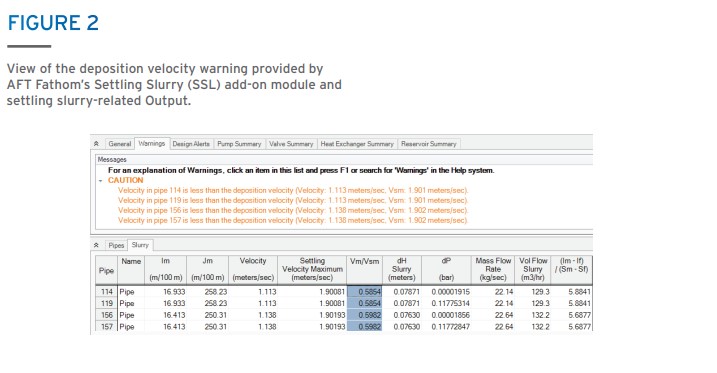

Papagari approached this problem with AFT Fathom’s Settling Slurry (SSL) add-on module to consider the additional hydraulic effects of slurry flow, including identifying if any areas had deposition concerns. A model was built and validated against plant data by adjusting pipe resistances. Non-standard frictional losses, such as those through heat exchangers, were modeled using resistance curves from Pressure Loss vs. Flowrate information. The model also accommodated temperature dependent fluid properties as the fluid was heated and cooled through heat exchangers.

Solutions & Benefits

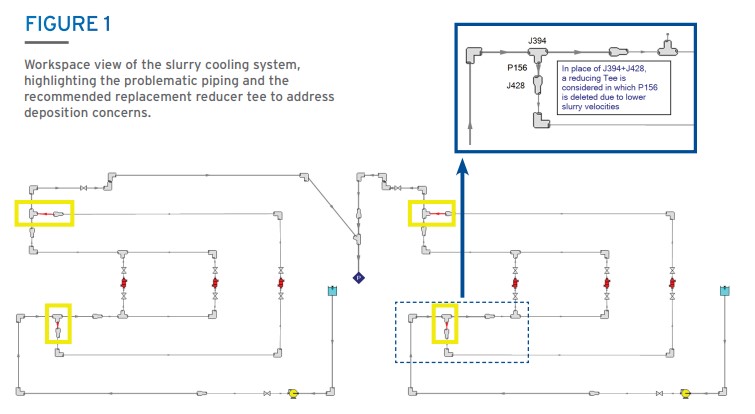

The model identified several slurry deposition areas (Figure 2) which were later confirmed by observation during a system turnaround. This deposition caused higher system losses which reduced the slurry recirculation rate and caused reliability issues.

Papagari suggested replacing a problematic 8-inch pipe with a reducer tee to maintain high fluid velocity. Along with this, other modifications on pump suction and discharge piping were suggested to reduce friction and increase circulation through pump. These changes increased reliability by avoiding deposition and simultaneously increased recirculation rate by 15%.

The piping changes were so effective that an up-sized replacement pump to further drive flow was canceled, a capital cost savings of $435K. The improved reliability and reduced shutdowns further added approximately $247K in savings per year.