Seawater Cooling System Modifications Eliminate Pump to Save 5.5MW in Ultra Mega Power Plant

AFT Impulse™ Case Study

Power Generation | Tata Consulting Engineers

“AFT Impulse was very easy to adopt, creating any number of variations was easy, and the study could be completed in the short given time.”

– C Suresh Ram, Tata Consulting Engineers Limited

PROBLEM

- Poor pump operation in independent, single-pass seawater cooling systems

- The plant owner proposed interconnecting systems to

- Improve operating flexibility

- Reduce energy use

ANALYSIS

- An AFT Impulse model was calibrated to within 2% error from field data

- 12+ scenarios were tested interconnecting systems and confirming adequate flow distribution

SOLUTION

- Determined connecting 4 of 5 units could operate 7 of 8 connected pumps, saving 5.5MW in energy

- Transient pump trip analysis confirmed no need for additional surge equipment

Ready to try AFT Impulse?

Problem Explained

C Suresh Ram, Tata Consulting

Engineers, was tasked with assessing

a coal-fired Ultra Mega Power Plant

cooling system to address poor

pump operation while ensuring

any modifications do not introduce

waterhammer or surge concerns.

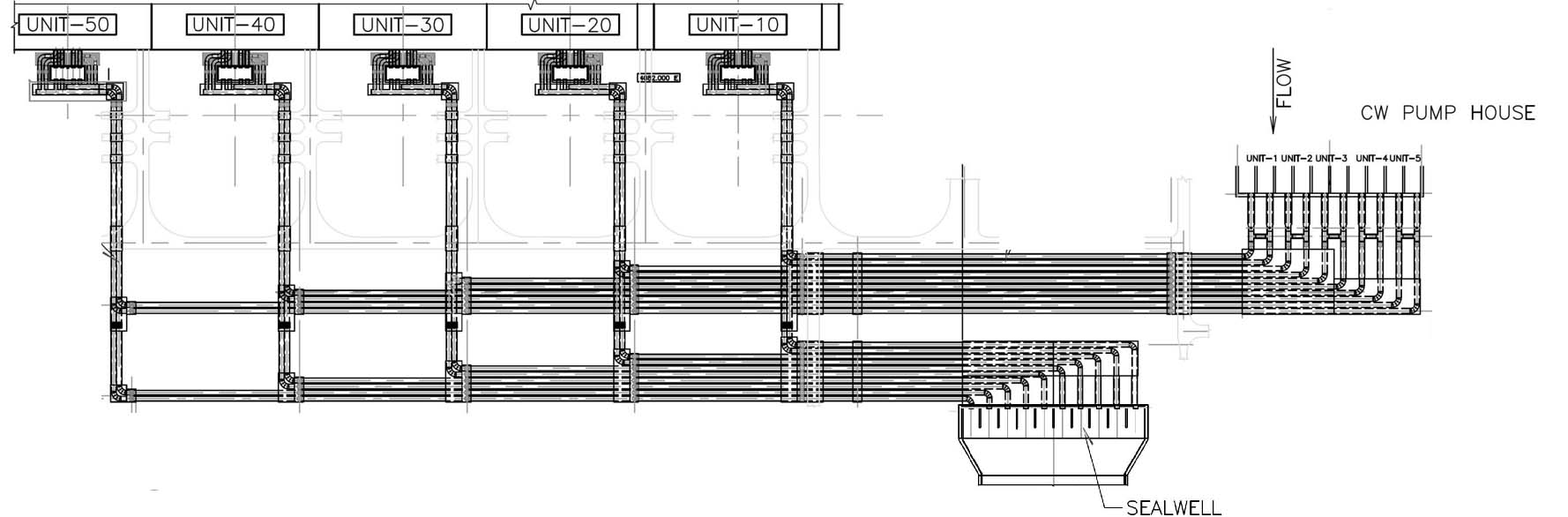

The plant consists of five units, each

cooled by independent once-through

seawater cooling systems. Each cooling

water system is driven by two parallel

pumps each with a rated capacity of

63,000 m3/hr (277,000 gpm).

The owner proposed interconnecting

the pumps of multiple units to reduce

the number of pumps necessary to meet

design requirements, reducing energy

and improving operational flexibility.

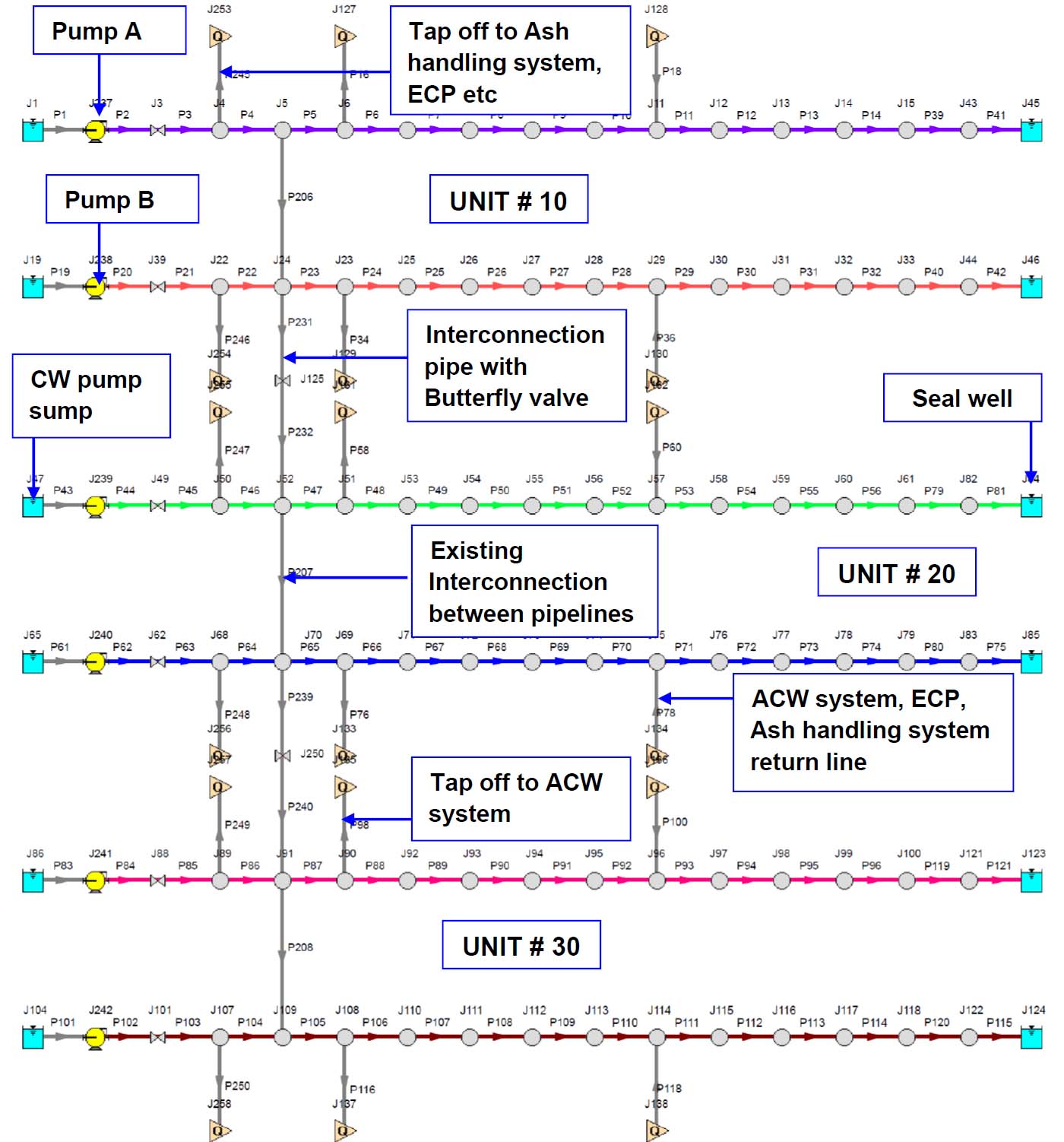

The existing system, as drawn and as

modeled, is found in Figure 1.

Tools & Analysis

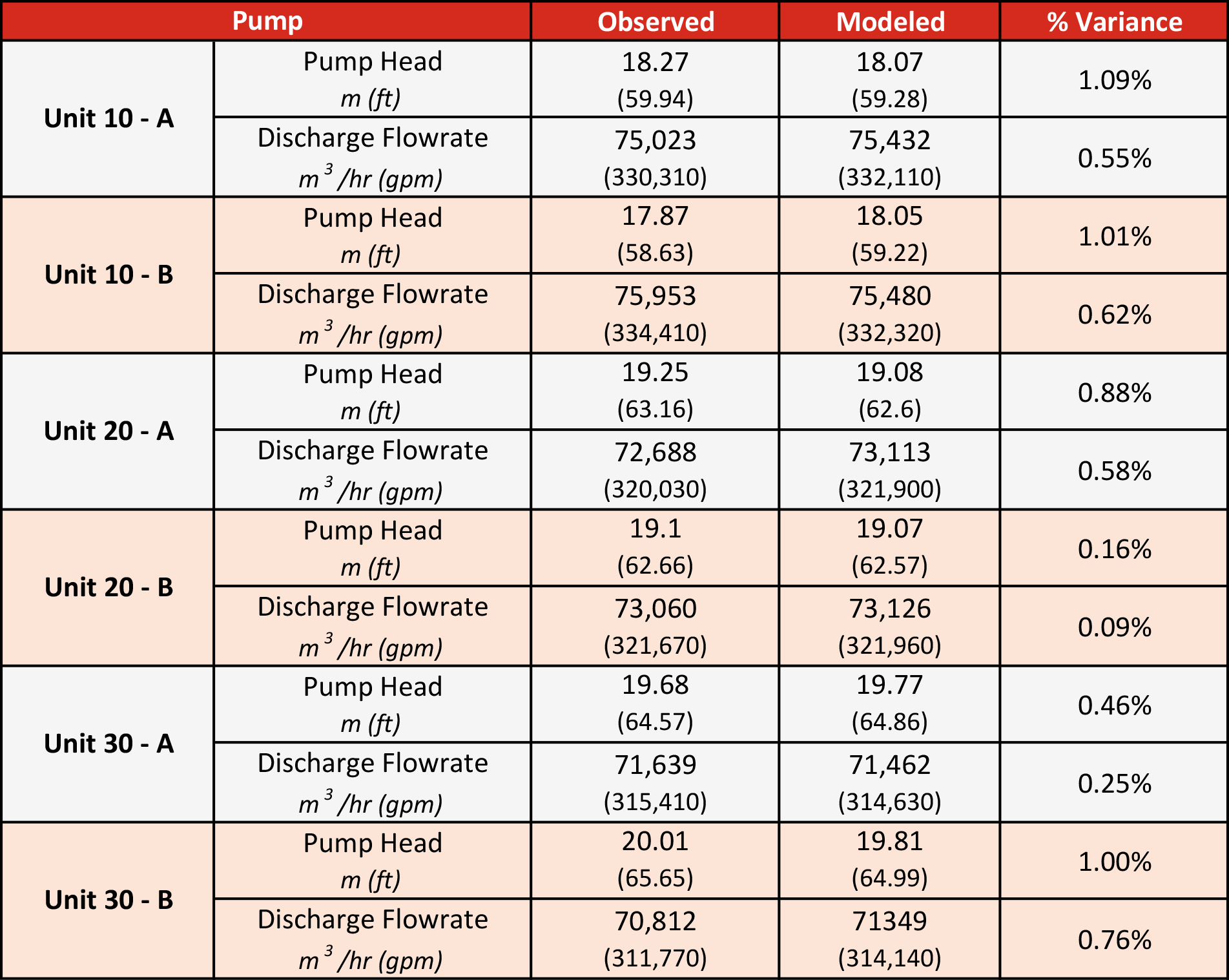

Ram’s analysis began in AFT Impulse’s

steady-state solver to calibrate the

model’s pipe roughness to match pressure

and flowrate measurements.

Frictional loss was estimated as the

system lacked pressure measurement

instruments. The calculated frictional

loss was consistently less than the

original design loss, indicating oversized

pumps leading to poor performance. A

comparison between the calibrated model

and observed data is found in Table 1.

The calibrated model was then used to

evaluate cases with various parallel units

connected. It was vital to confirm adequate

flow distribution to each condenser unit,

testing the system with any one of the

connected pumps off in turn. This process

was performed with three, four, and all five

units connected.

Solutions & Benefits

The sensitivity study found only four interconnected units met all

condenser requirements with any seven of the eight connected

pumps, reducing energy requirements by 5.5 MW and improving

pump operation.

However, the proposed changes required the system to be reevaluated for hydraulic transients. The new study was to confirm the adequacy of a previous study’s valve closure behavior and surge protection equipment. Ram’s study evaluated a range of pump trips using built-in Four Quadrant curves, from planned trips of each pump individually to the worst-case sudden power failure to all working pumps.

In all tested cases, the transient pressure extremes remained within

pipe design limits, the system stabilized to adequate final flowrates,

and pumps stayed below manufacturer specifications for maximum

reverse speed. Not only did the interconnected design improve

steady-state operation, Ram’s transient study confirmed no further

surge mitigation was required.

Ram noted AFT Impulse had a short learning curve with flexibility to

evaluate the full range of steady-state and transient requirements;

vital as the project was under tight deadlines.