AFT Fathom Helps Reduce Power Consumption by 40% at Petrochemical Plant

AFT Fathom™ Case Study

Ingenero Technologies Pvt. Ltd. | Hot Oil Network | Chemical & Petrochemical

“The results of the (AFT Fathom) validation model provided a

lot of insight into possible improvement options which

were inconceivable by plant data analysis alone.”

PROBLEM

- Excessive pressure drop across control valves led to significant operating costs

- Unsure where design and operating anomalies may be occurring

ANALYSIS

- An AFT Fathom model was calibrated for the physical system within 5% error

- This model was used to identify and size replacements for flow elements and control valves

SOLUTION

- The client saved more than $300,000 per year in energy costs due to the review

- The model provided insight inconceivable by plant data analysis alone

Ready to try AFT Fathom?

Problem Explained

Ingenero was able to save their client over $300,000 per year in energy costs after the client requested an analysis of a hot oil network in a petrochemical facility. They wanted to determine practical and cost-effective options to reduce power consumption and make the operation more energy efficient. The network used high pump discharge pressure and the pressure drops across certain control valves were excessively high.

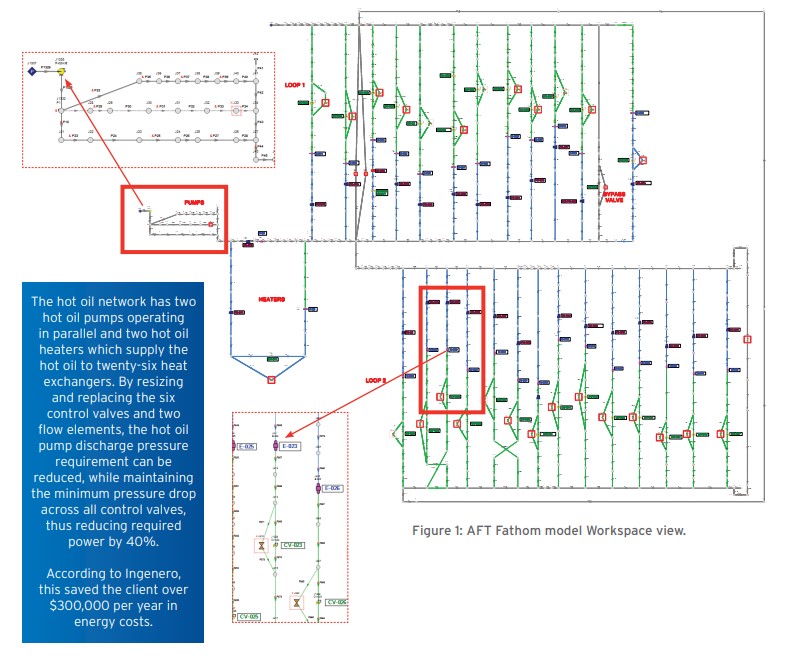

The petrochemical production facility’s hot oil network has two hot oil pumps operating in parallel and two hot oil heaters supplying hot oil to twenty-six heat exchangers. The laterals to individual exchangers have control valves and flow elements. The plant was being operated at full load and the hot oil supply flow rates to individual consumers were at the maximum.

The preliminary examination of plant operating data revealed that the pressure drops across certain control valves in the network range of 8-9 kg/cm2 (785-880 kPa / 115-130 psid). Ingenero proposed simulating the system using AFT Fathom so they could pinpoint and eliminate any design and operating anomalies in the network.

Tools & Analysis

The model was validated against the stable operating data reflecting the maximum required flow through individual exchangers. The control valves in the AFT Fathom model were provided with the flow reading values as inputs and the model calculated the required Cv values for all the control valves. Based on the model-predicted Cv values and the Cv vs opening characteristics available in the control valve datasheets, operating valve openings were predicted using Excel regression functionality. These predicted opening values were cross-checked against the control valve opening values provided in the plant data. It was observed that the deviation was within the +/- 5% range, indicating a good match.

The model-predicted pressures also showed an excellent match (+/-5%) with the plant pressure measurements available at various locations in the hot oil network. Based on this, it was concluded the AFT Fathom model was an accurate representation of the actual performance of the hot oil network.

Solutions & Benefits

The results of the validation model provided a lot of insight into possible improvement options which were inconceivable by plant data analysis alone. It was decided that in terms of cost-effectiveness and ease of implementation during plant shutdown, the most practical option was to modify certain flow elements and control valves in the network.

The AFT Fathom model helped them evaluate various configuration changes. The final recommendations were:

- Minimum pressure drop (7 kg/cm / 685 kPa / 100 psid) was observed across flow control valve for exchanger E-023. By resizing and replacing the control valve for exchanger E-023, the hot oil pump discharge pressure can be reduced by 5.9 kg/cm2 (580 kPa / 84 psi), while maintaining the minimum pressure drop across all control valves at 0.5 kg/cm2 (50 kPa / 7 psid).