AFT Impulse Helps Resolve Overpressure Safety Issue By Modifying Subsea Valve Operations

AFT Impulse™ Case Study

Procure SPA | Desalination Plant | Water & Wastewater

“The client had previously contacted the original equipment manufacturer

as well as the original EPC firm regarding the issues, but neither

contractor could find the source of the vibration or the causes for failure.”

-Cristian Lira, Senior Consultant

PROBLEM

- Non-programmed shutdowns of Energy Recovery System (ERS) in desalination plant reduced production capacity by 6%

- Equipment manufacturer and original EPC could not determine issue

ANALYSIS

- AFT Impulse was calibrated to existing system, revealing vacuum pressure issues during shutdown

- Hydraulic chimney (standpipe) was sized and analyzed to reduce vacuum pressures

SOLUTION

- Hydraulic chimney was implemented into existing system, reducing minimum pressure by 55.5%

- Average shutdowns per day cut in half, saving plant money over purchasing lost

production

Ready to try AFT Impulse?

Problem Explained

Cristian Lira, Senior Consultant at Procure SPA, performed a root cause analysis of an existing Energy Recovery System (ERS) within a major desalination plant. The goal of the study was to recreate the ERS shutdown to determine the impact on the brine discharge pipeline. This would inform a proposed solution for constant, non-programmed, shutdowns.

The desalination plant contains nine Reverse Osmosis (RO) racks, each one with a reciprocating ERS (Figure 1). High pressure brine, the waste product of RO, is sent to the ERS racks to recycle its high-pressure energy. The ERS’ six reciprocating pistons transfer the waste brine’s pressure to fresh sea water feed for the RO membrane vessels.

Their client requested the study due to frequent, non-programmed shutdowns of the ERS racks (on average 2 shutdowns per day, with a duration of 5-7 hours each). The shutdowns reduced the plant’s capacity to about 94% of its nominal capacity, losing around 12,000 m3 (3,200,000 gal) in desalinated water production per day.

Tools & Analysis

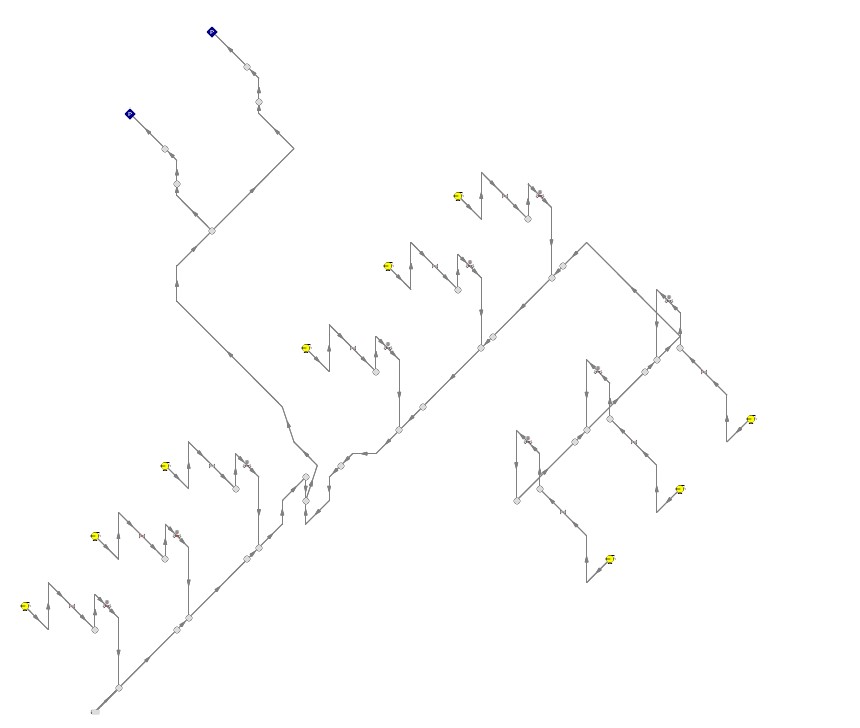

Lira and his team used AFT Impulse to create a calibrated model of the system. This included 9 ERS racks modeled as positive displacement pumps, valves which simulate the 30 second shutdown of an ERS rack in different configurations (determined according to operational data) and 2 brine tanks. The brine tanks have two feeding lines each but were operating with only the upper lines (Figure 2).

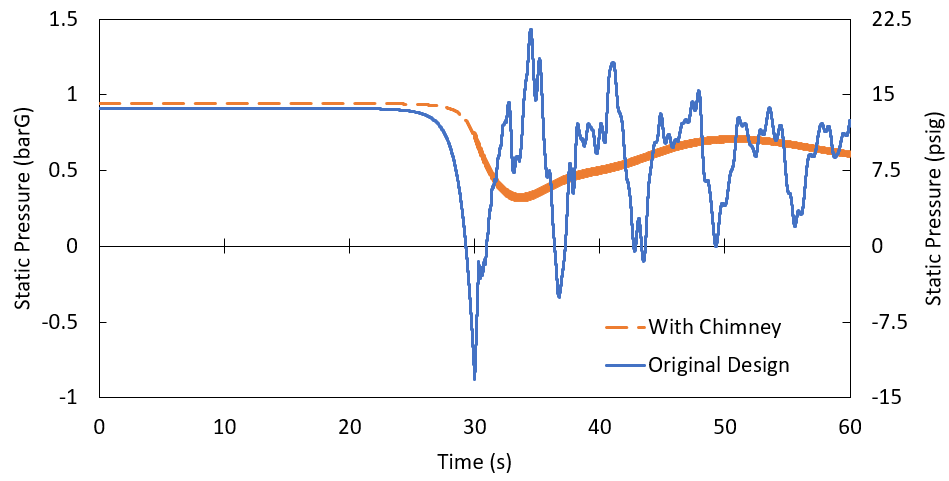

After running the base scenario (calibrated with the system’s control philosophy and operational data), Lira and his team found that when an ERS rack shut down, vacuum pressure was created inside the brine discharge pipeline. This condition was highly detrimental for the system as vacuum breaker valves on the ERS rack headers allowed air into the system. This entrained air then accumulated at a high point which generated further fluctuations on the discharge pressure.

Solutions & Benefits

Procure’s hydraulic team evaluated the installation of a hydraulic chimney ((essentially a standpipe) at the discharge line of each ERS rack. This chimney would prevent the absence of brine and generate counterpressure after a shutdown, avoiding the vacuum pressure issue. Each chimney was about 8 m (26 ft) high and 0.35 m (1.2 ft) in diameter.

Confident in their modeled results (Figure 3), Lira and his team received authorization from the client for the construction of the chimneys, one each for the 9 ERS racks. After the installation and operation of the hydraulic chimneys, pressure on the brine discharge line became steadier. Pressure oscillations decreased by 34.8%, with minimum pressures values increasing by up to 55.5%. Pressures at the discharge line no longer reached vacuum pressure values during shutdowns.

Non-programmed shutdowns were reduced to an average of 1 shutdown per day, with a duration of 4-4.5 hours each. With these results, the desalination plant increased its throughput by 6,000 m3 (1,585,000 gal) per day. This led to a savings of $175,000 per year over purchasing supplemental production.

Additional Fact: Since start-up, the entire system had run with low reliability and high failure rates due to low frequency and random vibrations. During the first 12 months, failures occurred at the ERS equipment, piping system, instrumentation, and auxiliary structures. Reliability, uptime, mean time between failures, and maintenance costs were far from expected and constantly exceeded budget. The client had previously contacted the original equipment manufacturer as well as the original EPC firm regarding the issues, but neither contractor could find the source of the vibration or the causes for failure.

Figure 2: AFT Impulse Workspace View includes (9) ERS racks (modeled as positive displacement pumps), (9) valves to simulate the shutdown of an ERS rack in different configurations, and (2) brine tanks.