Nuclear Fusion Project Successfully Completed with AFT Fathom

AFT Fathom™ Case Study

Larsen & Toubro Construction | Water Cooling System | Nuclear Power

“All combinations were modeled in a single system & analyzed

easily, where it is near impossible to do this by manual methods

and get accurate results”

– M. Arunkumar, Process Engineer

PROBLEM

- Cooling water system design for nuclear fusion project in France

- Operating pressures had to be under strict limits near certain components

ANALYSIS

- AFT Fathom helped the engineers create the initial system design

- Ultimately allowed for easy testing of operational conditions to meet the pressure regulations

SOLUTION

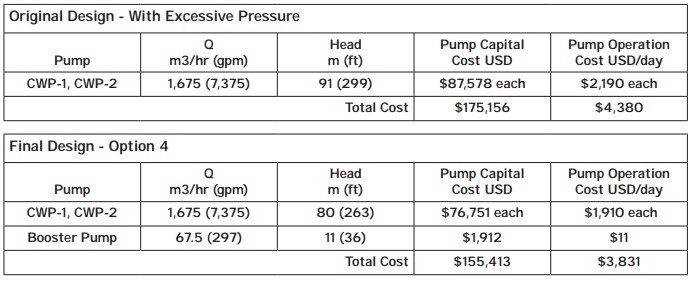

- A booster pump reduced pressures in concerned areas by reducing the head requirement of the main pumps

- 11% and 12% reduction in capital and operating costs, respectively

Ready to try AFT Fathom?

Problem Explained

For decades nuclear fusion has been hailed as the future energy source of humankind – a source of virtually unlimited green energy. Current projects are directed towards fusion research. Larsen & Toubro Construction (L&T) was responsible for Detailed Design, Engineering, Procurement and Supply of a large cooling water system for a nuclear fusion project being constructed in France.

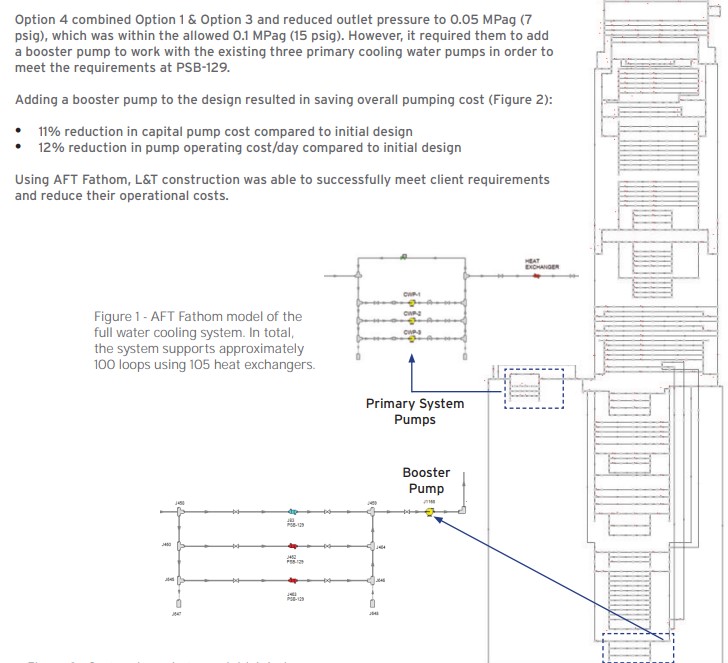

The project specifically focuses on the Component Cooling Water System, which supplies about 100 loops.

Tools & Analysis

Arunkumar built an AFT Fathom model of the system. The purpose of the hydraulic study was to determine the optimum pump head of cooling water pumps in order to satisfy outlet pressure requirements for the equipment being cooled.

During steady-state hydraulic analysis using AFT Fathom, the cooling water pressure requirement had been met at every outlet except for one piece of equipment. L&T investigated four options to reduce the cooling water pressure at the pump outlet. These options were modeled as different scenarios in the model. An unexpected outcome from the selected option was used to reduce overall pumping costs by 12%.

The cooling water system consists of plate heat exchangers, horizontal centrifugal pumps, pressurizers, water polishing unit, and equipment that needs cooling; as well as the associated piping, valves and instrumentation. For this particular project, cooling water pressure at the equipment outlet is restricted within certain values for each area that needs cooling.

Solutions & Benefits

The steady-state analysis showed the outlet pressure at equipment PSB-129 was 0.24 MPa-g (35 psig) which was higher than the limited value of 0.1 MPa-g (15 psig). Hence, the challenge was to analyze and reduce the outlet pressure below the maximum pressure limit.

In order to reduce outlet pressure, the resistance in the return line had to be reduced. The Scenario Manager tool enabled Arunkumar to model & check various options to reducing outlet pressure under a single parent scenario. Below are the possible options he determined could reduce the outlet pressure:

Option 1: Shifting of heat exchanger to downstream of pumps

Option 2: Increased line size of cooling water return line

Option 3: Use of booster pumps at outlet of PSB-129

Option 4: Shifting of heat exchanger and using a booster pump