Ingenero Solves Pipe Failures in Mixed Bed Polishers Using AFT Impulse

AFT Impulse™ Case Study

Ingenero Technologies | Mixed Bed Polisher | Chemical & Petrochemical

“Being a pressure based transient flow modeling tool, AFT Impulse

helped us understand the magnitude of an unknown force

and specifically pinpoint which particular step was responsible for

the highest magnitude.”

-Swapnil Paingankar, Specialist Mathematical Modeling

PROBLEM

- Failure of MBPs during valve operations damaged piping

- At any given time 2 of 9 MPBs were under repair, reducing power generation and causing lost production time

ANALYSIS

- AFT Impulse model was used to model the valve operations

SOLUTION

- The precise operational step which caused the failure was identified

- An alternate valve sequence was determined which solved the problem. New sequence was a success

Ready to try AFT Impulse?

Problem Explained

Ingenero Technologies’ Swapnil Paingankar, SpecialistMathematical Modeling, and Dhiresh Mahajan, Assistant General Manager of Special Projects, oversaw the analysis and remediation of a client’s existing resin mixed bed polishers (MBPs) in a petrochemical facility.

MBP’s are used to treat condensate and demineralized water for boiler feed water systems. In total, nine MBPs needed to be fully operational, and at any given time two were experiencing a failure of the middle collector due to severe physical damage such as bending and breaking. Their client was concerned about the continuous repair costs and the lost production time.

Ingenero was asked to analyze and suggest possible fixes to reduce the middle collector failure. One MBP, which was reported to have the most frequent middle collector failure, was chosen for the analysis.

Tools & Analysis

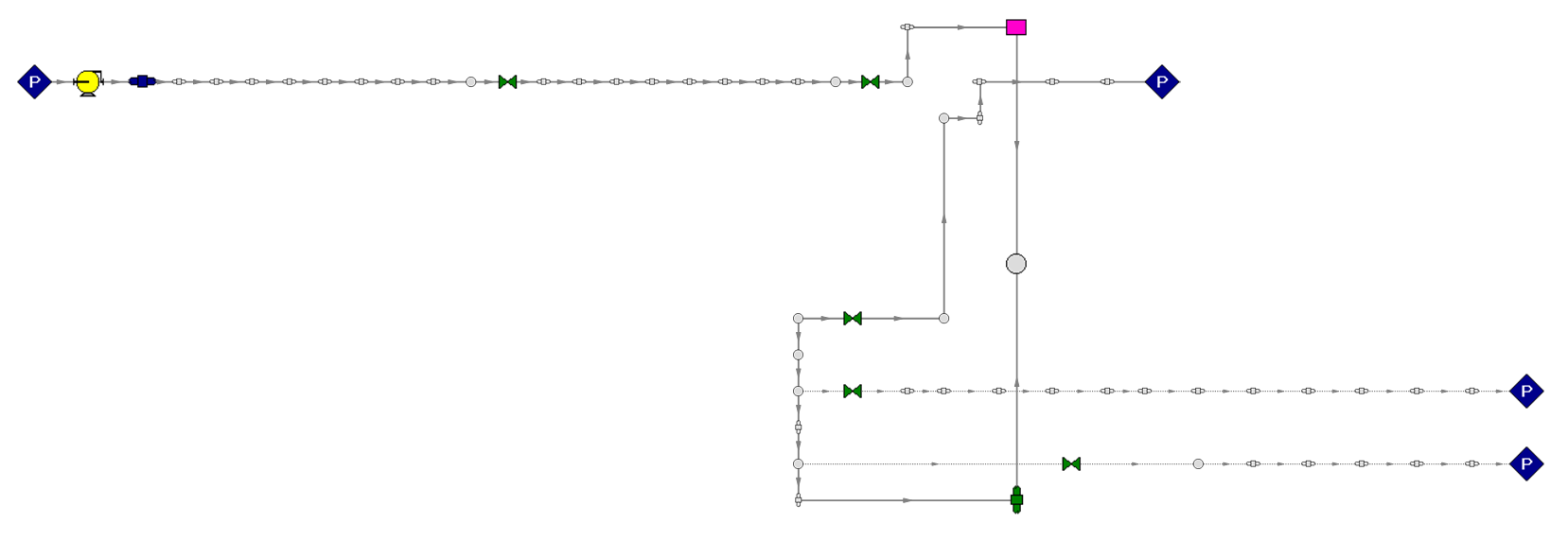

The team analyzed the regeneration operation by incorporating the sequences used to open and close the butterfly valves in the piping system associated with the failing MBPs. (See Figure 1)

After examining the regeneration operation, Paingankar and Mahajan knew there was a force which caused the middle collector piping element to fail. They suspected the failure was due to a possible pressure surge in the MBP middle collector.

The resin bed sections above and below the middle collector were modeled as two separate pressure reducing stations. The characteristic friction factor for these packed resin sections was calculated from the operating data of flow and pressure drop under normal operation.

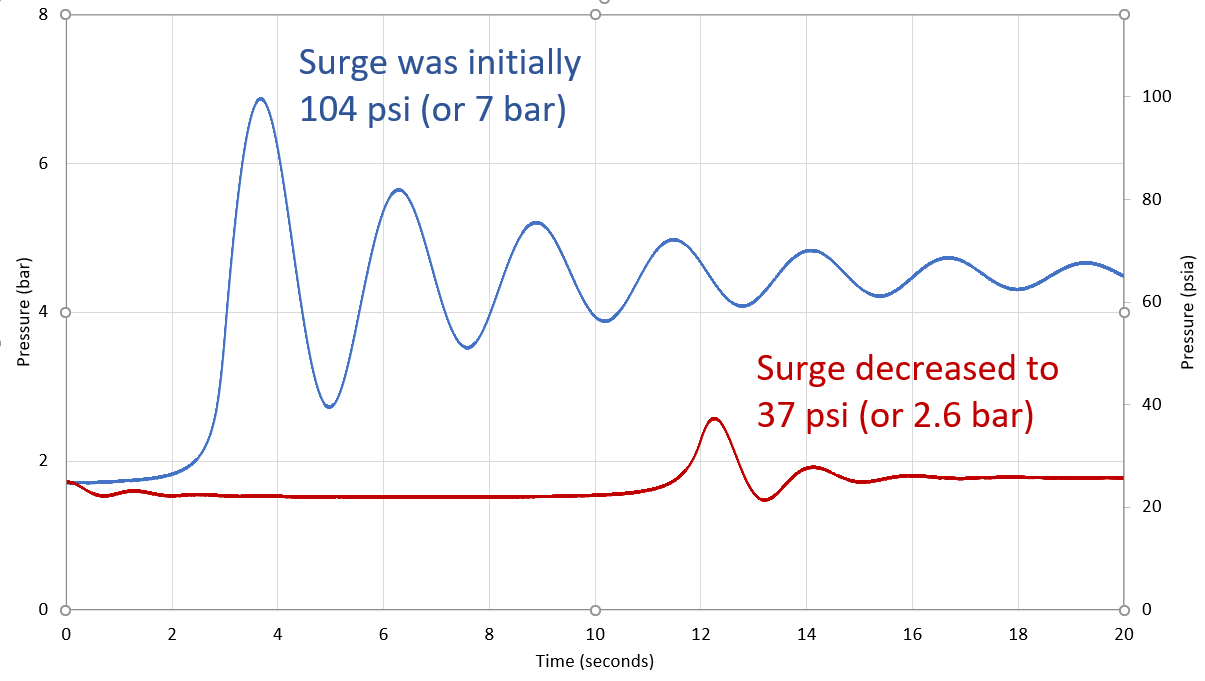

After simulating transient scenarios based on various valve closures/openings and field observations, it was evident the middle collector was experiencing a pressure surge as high as 104 psi, or 7 bar, during certain step changes. Based on this surge, three additional scenarios were simulated and allowed Ingenero to confidently suggest improvements in the regeneration sequence to minimize failures.

Solutions & Benefits

One recommendation reduced the potential pressure surge to 37 psi, or 2.6 bar (see Figure 2).

AFT Impulse helped Paingankar and Mahajan understand the magnitude of this force and specifically pinpointed which step was responsible for the highest magnitude. It also helped them carry out sensitivity analysis with respect to modifying the valve “open-close” sequence timings and evaluate whether reduction in the magnitude of the surge pressure was possible.

This project was awarded to Ingenero Technologies as a challenge to their repertoire of high end expertise of system root cause analysis. The status today is that the problem is eliminated.

With AFT Impulse, Ingenero Technologies was able to successfully recommend sequence modifications to their client.

“These MBP failures were looked at by the client’s in-house technical and engineering departments as well as a few globally reputed consulting organizations over 5 to 6 years without incremental improvement of the situation, let alone complete success”

FIGURE 1: AFT Impulse model showing the Mixed Bed Polisher system Ingenero was asked to analyze and successfully modified utilizing innovative sequence modifications.