AFT Fathom Heat Transfer Capability Used in Power Plant HVAC System

AFT Fathom™ Case Study

Energoprojekt Katowice | HVAC Hot Water System | Power Generation

“Obtaining results in a short time gives the possibility for checking

other than typical solutions – a very important aspect in the

design process.”

– Agnieszka Markwica , Mechanical Engineer

PROBLEM

Design a new heat exchanger plant, accounting for diverse operating conditions

- Normal Operation

- Emergency Bypass and recirculation

- Preheating

ANALYSIS

- Used scenarios to analyze operating conditions, and varying control valve setpoints

- Heat transfer analysis provided water temperatures from heat exchangers

SOLUTION

- Informed orifice size for maintenance and operating conditions

- Sized pump to operate in different conditions

- Workspace customization made the system intuitive and readable

Ready to try AFT Fathom?

Problem Explained

Water utilities for heating and cooling are critical to the safe and effective operation of many power plant systems. These utilities are also valuable for heating a plant’s surrounding infrastructure, providing HVAC heating to buildings from a plant’s existing heating infrastructure. The design of these infrastructure systems is subject to a range of operating conditions, such as variable seasonal heat demand, or changing demand from day to night for continuously operating power plants. These systems must also consider start-up and emergency conditions, requiring a robust system capable of a wide range of operating points.

Agnieszka Markwica with Energoprojekt Katowice was tasked with modeling the hot water network of a power plant in AFT Fathom, capturing heat to deliver to the surrounding buildings’ HVAC via heating water. Markwica was to consider the system’s heat transfer requirements, as well as alternatives when heat requirements shifted or consumers were temporarily closed off.

Tools & Analysis

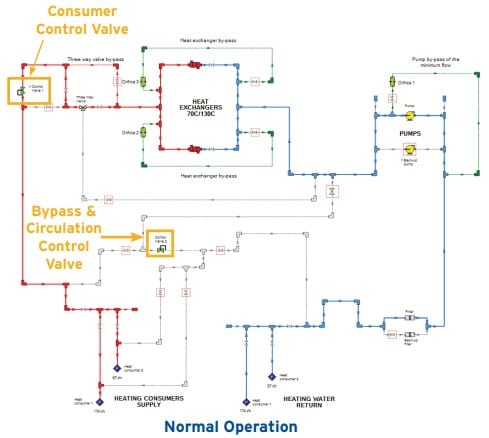

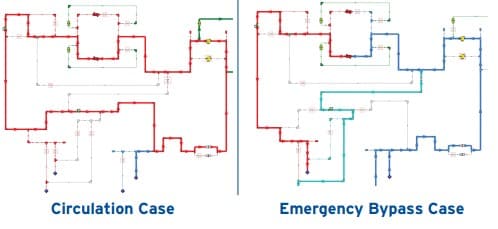

Markwica began by making a precise model of the system infrastructure, relying on technical documentation for fittings and instruments and system data for piping dimensions. Complex components like heat exchangers were modeled as resistance curves, capturing pressure loss data across a range of flowrates. Heat exchanger temperature considerations were similarly modeled via the Controlled Downstream Temperature model. Markwica also color-coded the model, indicating colder feed water in blue and hot delivery water in red. Color coding made the model immediately readable to other engineers and the client. Figure 1 shows a Workspace diagram of normal operation, highlighting the control valve elements used for the alternative emergency and circulation operating cases below.

With an established model, Markwica sized the system’s pump according to the design required flow and corresponding pressure requirement. This single pump would provide the HVAC system’s wide range of required flows, anywhere from 20 m-tons/hr (22 tons/hr) at minimum circulation flow, 67-174 m-tons/hr (74-192 tons/ hr) in emergency cases, and up to 241 m-tons/hr (265 tons/hr) at normal operation.

Solutions & Benefits

According to Markwica, AFT Fathom provided immense value in this analysis by capturing the complications of a large, interacting heat transfer system across many operating conditions. Each case could be examined in detail without completely isolated models, ensuring that a single design could meet all the potential operating conditions efficiently from VFD and control valve considerations. After the infrastructure of the system was built out, it was trivial for Energoprojekt and their client to test alternative pipe geometries or components within the system.

System design is a challenge, especially when considering multiple operating points and system requirements. Markwica put it best that AFT Fathom provided “results in a short time, providing the possibility tor checking other than typical solutions”, revealing the most optimal solution instead of the most immediately apparent.