AFT Arrow Powers Gas Turbine Analysis at Fern

AFT Arrow™ Case Study

Fern Engineering, Inc | Gas Turbine System | Power Generation

“[AFT Arrow has] the ability to model critical (i.e. sonic) orifices

or venturis and the capability to model a large number of elements…”

-Hector Bourgeois, Fern Engineering President

PROBLEM

- Extreme exhaust gas temperature (EGT) spread was impacting lifespan and operation of turbine components

- EGT spread was caused by variations in quantity of supplied fuel

ANALYSIS

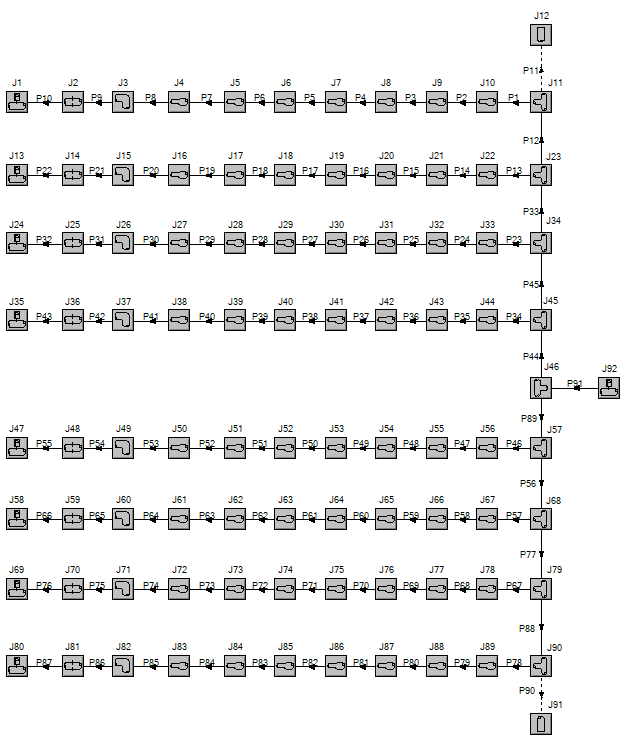

- AFT Arrow modeled supply system’s fittings, lengths, and supply proximity to determine fuel supply variation

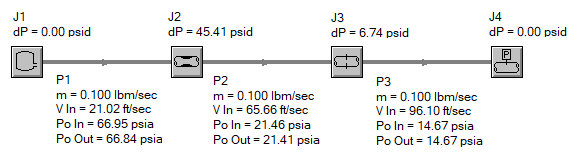

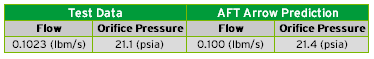

- Arrow was benchmarked for sonic choking against test data

SOLUTION

- Model of system estimated flow variation due to expected tolerance variation, which then informed EGT spread

Ready to try AFT Impulse?

Problem Explained

As green energy grows through its awkward teenage phase, the world looks to natural gas to as a clean-ish way to meet energy demands and smooth the transition to renewable energy. Liquefied natural gas (LNG) is a way to transport this fuel where gaseous pipeline transport is unavailable, for example across an ocean. LNG is liquefied at one terminal by cooling the gas to -160°C or below (<-256°F), loaded into special tankers for transport, then turned back into gas at its next terminal to distribute via pipeline.

The LNG loading process occurs through loading arms, constructed of expensive low-temperature alloys for cryogenic operation and designed to consider the moving vessel the arm is attached to. An LNG terminal might have two to five loading arms for different purposes. In an emergency shutdown, flow through these arms must be suddenly halted by closing a sequence of valves, opening vent valves, and tripping transfer pumps. The sudden deceleration of flow results in pressure surge, potentially exceeding pipe design pressures and causing extreme pipe stress, further worsening an emergency.

Tools & Analysis

A research team at Lamar University led by Xinyu Liu evaluated the surge results from an LNG loading emergency shutdown. The system, as constructed in AFT Impulse, is found in Figure 1, highlighting the closing valves, opening vent valves, and tripping pumps. In additional to a scenario with the emergency system working as intended, the team considered five cases where the system malfunctioned, as listed below.

- Emergency system working properly

- Pumps fail to trip

- Vent valves fail to open

- Pumps fail to trip and vent valves fail to open

- One of four pumps fail to trip

- One of three vent valves fail to open

In addition to these six cases, the team also evaluated valve characteristics for the closing and opening valves. Valve characteristics relate a valve’s open percentage to its Cv, in essence describing how a valve controls flow through it as it opens or closes. These characteristics can drastically impact a surge pressure response, so the team performed sensitivity analysis for comparison.

Solutions & Benefits

The maximum surge pressure in each case was compared to the pipe’s design pressure of 220 psia (15 bar). Only in the worst-case scenario where both the pumps fail to trip and the vent valves fail to open was this design pressure exceeded, as found in Table 1.

While surge pressure did not exceed the design pressure in most cases, the resulting transient piping forces created major concerns. The imbalanced force would cause stress, deflection, and vibration as the pressure wave transmitted through the system. The worst-case with pumps running and vent valves closed saw forces exceed 12,000 lbf (53 kN) near the pump transfer valves.

The team exported their force results from AFT Impulse into ANSYS for a time history analysis. They could further assess displacement, vibration, and pipe stress as seen in Figure 2.

The team emphasized the value of performing system sensitivity analysis with a simulation model, especially with the dangerous consequences of surge during an emergency. By considering forces in addition to pressures, the team could reveal further pipe stress concerns. As natural gas further supplements energy requirements, the safe transport during LNG loading and unloading will only become more vital.

Table 1: Comparison of maximum surge pressure for each transient case. Only the worst-case with both pump and vent valve failures exceeded the pipe design pressure of 220 psia (15.2 bar)