Analysis Using AFT Fathom Reveals Root Cause for Fire Pump System Over-Pressurization

AFT Fathom™ Case Study

CB&I Inc. | Fire Protection System | Power Generation

“As a modeling solution, [AFT Fathom and the XTS Module]

provide the ability to emulate conditions that would otherwise

be unattainable.”

– Charles Williamson, P.E., Senior Engineering Analyst

PROBLEM

- Overpressure issue during pump start-up, exceeding design pressure by 25 psig (1.7 barg)

- Potentially caused by pump overspeed, an unresponsive relief valve, or a combination of factors

ANALYSIS

- A model was calibrated to the physical system through pump field tests, pipe drawings, and loss data

- Pump ramp-up and relief valve opening was predicted

SOLUTION

- Found relief valve was too slow to react, opening in 10-20 seconds instead of designed 3 seconds

- Resulting actual results tracked well with predicted results

Ready to try AFT Fathom?

Problem Explained

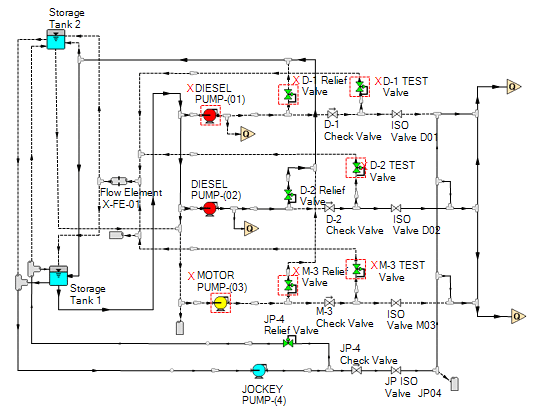

In an undisclosed facility, a fire pump system had an over-pressurization problem during pump starts, realizing discharge pressures of 200 psig (1379 kPa-g) in a system designed for a pressure of 175 psig (1207 kPa-g).

Charles Williamson, P.E., senior engineering analyst at CB&I, was asked to determine the root cause of the pressure surge and make recommendations for corrective action. The design details of the system and a sparse dataset were all that the owner could provide for the analysis.

The pressure transient was the result of either pump over speed at startup or an unresponsive relief valve. Williamson presumed both issues were occurring to a degree.

Tools & Analysis

Data for these two parameters were not collected originally. He used an innovative application of AFT Fathom and the XTS Module to reconstruct the unavailable test data for analysis.

Piping arrangement drawings, valve loss data, and pump performance test data were used to prepare an accurate physical model of the system. Multiple pump field tests were used to prove the calibration of the system over a wide range of operating points. With design and test detail provided, Williamson confirmed the model’s integrity and validity.

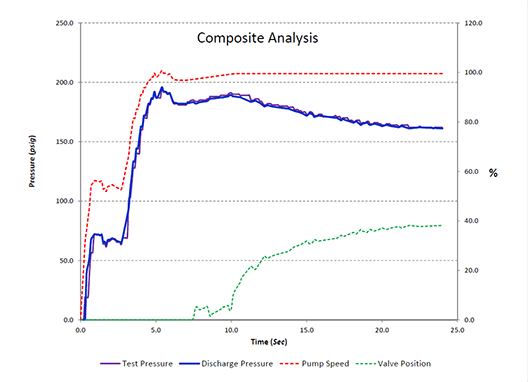

Williamson independently analyzed the effect of the pump speed and valve modulation on discharge pressure and combined these contributions to the original test data.

Solutions & Benefits

By use of an innovative approach and a partial differential relaxation technique, Williamson recreated a robust simulation of the test. This, of course was an estimate of how the equipment would need to behave, in order to produce the observed pressure transient. This transient simulation made it possible to reconstruct the test data that was not otherwise available.

Once the analysis was presented to the owner, they disclosed that a number of modifications had been performed on the relief valve which slowed the valve response time down considerably. It was estimated that the valve which was originally designed to open in ~3 seconds took as long as 10 20 seconds to respond. The remainder of the project was directed toward restoring the faster response time for the valve.