Dust Collection Systems Rebalanced After Manufacturing Facility Data Matches AFT Arrow Models

AFT Arrow™ Case Study

TruStile Doors, LLC | Dust Collection System | Manufacturing

“Using AFT Arrow made this project easier, cheaper

and more accurate than any alternative.”

-Jeremiah Osborn, Maintenance Engineer

PROBLEM

- Hardwood door manufacturing facility underwent modifications

- The dust collection process needed rebalancing

ANALYSIS

- AFT Arrow was used to model the existing system and proposed changes

- The highly branched system required robust calculations for flow distribution

SOLUTION

- System changes were implemented to rebalance the flow

- Measured data matched well with the predictions from Arrow

Ready to try AFT Impulse?

Problem Explained

Jeremiah Osborn, maintenance engineer at TruStile Doors, used AFT Arrow to model three systems used for dust collection at the hardwood door manufacturing facility in Northwood, Iowa.

These dust collection systems are essential to ensure employee safety and are an OSHA requirement in the wood processing industry. Dust collection is necessary to prevent explosions and to prevent long term eye and respiratory disease.

The existing Northwood systems have been modified extensively over the years to accommodate changing process conditions without any rebalancing work. The systems consist of a baghouse filter, a fan and ducting to each machine. The ducting is spiral wound galvanized steel.

Tools and Analysis

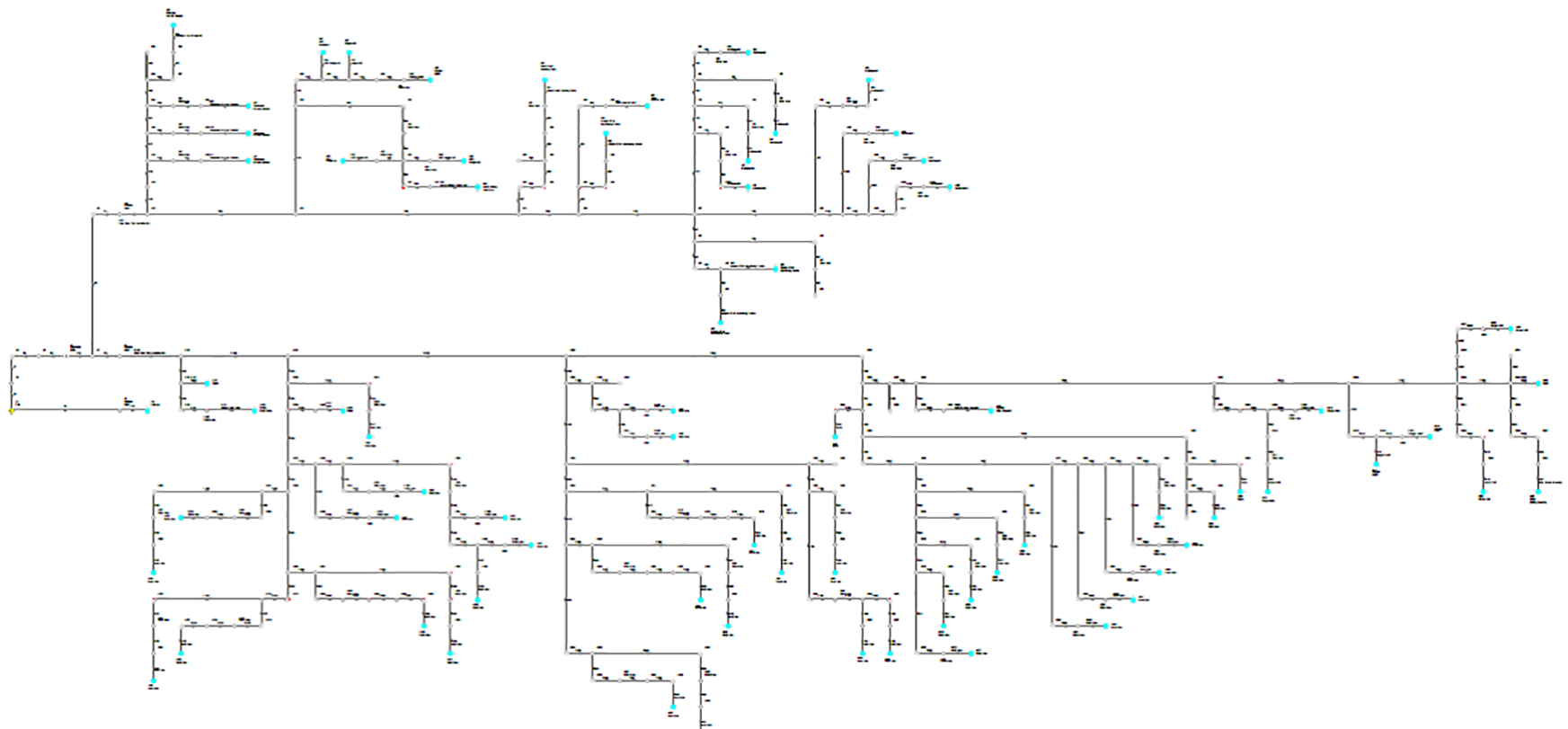

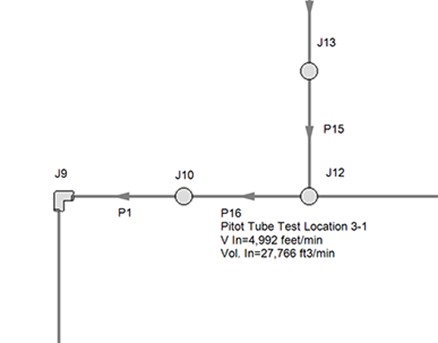

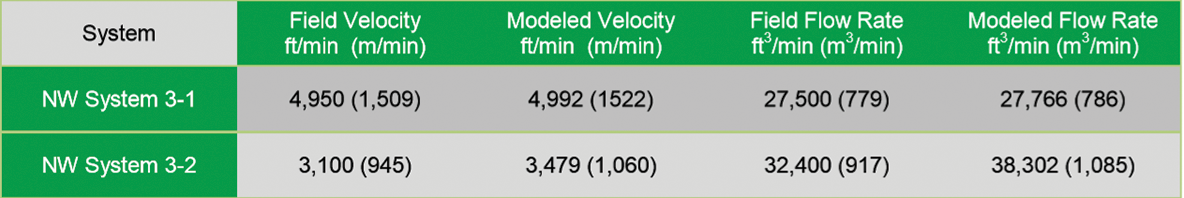

Osborn constructed AFT Arrow models to balance the airflow in the systems. Since all the models are heavily branched, only System 3 is shown in this case study (see Figure 1). The models and the results for Systems 1 and 2 are similar to System 3. Wood dust requires 4,000 – 4,500 ft/min (1219 – 1372 m/min) of airflow for adequate dust collection. Using a Pitot tube and manometer, the main trunk lines on each system were tested and compared to the model data (see Figure 2).

Solutions & Benefits

Asked to describe the benefits of using AFT Arrow, Osborn said “Using AFT Arrow to model these dust collection systems was much easier and faster than creating a tool in Excel and/or doing the calculations by hand. These systems are heavily branched, and AFT Arrow handled the complexity with ease. I was also surprised at how easily my models converged and how close they were to field measured data. AFT Arrow also gives me the capability to easily modify the systems when adding new equipment to see how it will affect other dust collection points. Overall, using AFT Arrow made this project easier, cheaper, and more accurate than any alternative.”