Digester Complex Heat Reservoir Recirculation System Hydraulic and Thermal Analysis Accomplished with AFT Fathom

AFT Fathom™ Case Study

Brown and Caldwell | Water Reclamation System | Water & Wastewater

“I modeled a boiler loop and several secondary heat exchanger loops to

simulate the heat loads gained and lost by the system. AFT Fathom was

able to do this simultaneously which is much more efficient than typical

Excel calculations.”

– Tyler Knight, Mechanical Engineer

PROBLEM

- Expansion of a wastewater digester system required flow and heat transfer analysis

- Existing Excel calculations were error-prone and tedious

ANALYSIS

- AFT Fathom re-modeled the existing system and its expansion to confirm operational reliability at the highest system demand

- AFT Fathom also confirmed thermal loads and process temperatures

SOLUTION

- Running two recirculation pumps, with one on standby, was found to meet the peak demand of the expansion

- Boiler return temperatures were predicted and used in the design

Ready to try AFT Fathom?

Problem Explained

Tyler Knight of Brown and Caldwell was tasked with developing a system curve and pump design points for heat reservoir recirculation supply and return (HRS/ HRR) loop pumps. The goal was to determine if existing heat reservoir recirculation pumps could deliver minimum 340 gpm / 1,300 liter/m to the heat reservoir loop to maintain the loop’s temperature. This required not only a hydraulic calculation but also a coupled heat transfer analysis of the system.

Knight included convective heat transfer on pipes to ambient. This was the third phase of a water reclamation plant project and Knight’s team inherited old Excel calculations from when the system was built in 2004 that were difficult to follow, tedious, and prone to mistakes.

Tools & Analysis

The team set out to re-model the system with both current reliability and future expandability in mind. With the next phase of the expansion scheduled to begin a few years out, Knight wanted to ensure the next engineer could easily understand and make modifications to calculate any new system parameters.

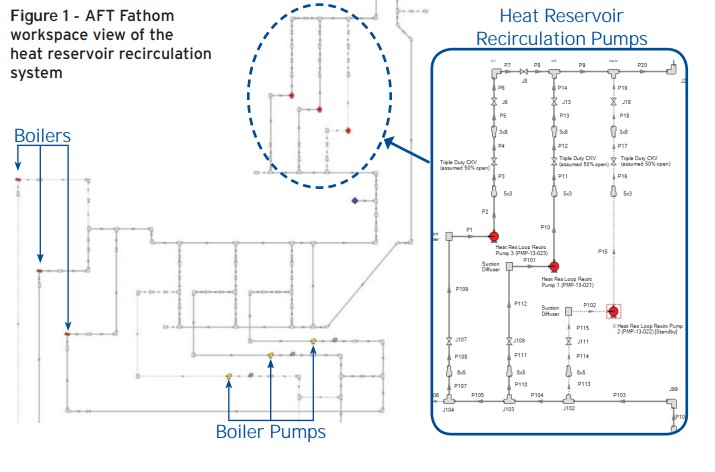

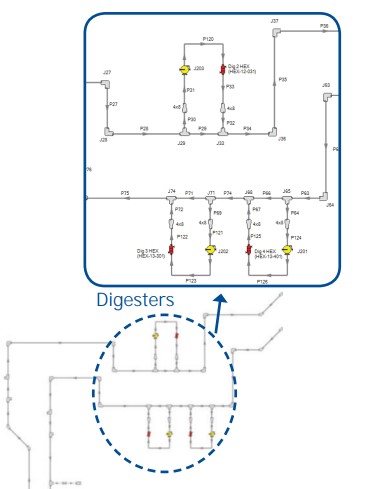

The existing system used heat reservoir recirculation pumps (PMP-13-021, 022, 023) to circulate hot water from the Boiler Building to the Digester Complex. At the Digester Complex, the hot water from the system is circulated through four different digester heat exchangers to heat the digester sludge. The goal was to have two heat reservoir recirculation pumps and two boilers in operation with one standby of each. The heat reservoir loop was sized using the peak heating demand and then modeled using AFT Fathom.

Solutions & Benefits

The outputs from the AFT Fathom model aligned closely with actual conditions. AFT Fathom was able to simultaneously model a boiler loop and several secondary heat exchanger loops to simulate the heat loads gained and loss, which was much more efficient than typical Excel calculations.

The model assumed worst case scenario (maximum heat and pressure losses) to verify heat reservoir system can meet peak demand. Important design parameters were verified and determined by the output from the AFT Fathom model including the minimum boiler return temperature and the approximate open percentage for the triple duty check valve on boiler circulation pumps. Since a portion of the model had already been in service, Knight was able to validate the model by comparing the results to the existing operation conditions which gave the team confidence in using the model and allowed them to quickly move forward with the design.