Crude Oil Booster Pump System Waterhammer Field Problem Solved with AFT Impulse

AFT Impulse™ Case Study

Beta Machinery | Oil & Gas Industry

“The software flexibility led to not only a greater understanding

of the system, but to a field validated model that was used

to solve the client’s significant water hammer problem.”

-Jordan Grose, Pump Systems Manager

PROBLEM

- Investigated a swing check valve slamming problem after pump shutdown in a crude oil booster pump station

- Unacceptably high pressures were generated

ANALYSIS

- AFT Impulse model was created and calibrated to measurements

- “What-if” scenarios were run on different potential solutions

SOLUTION

- The model showed a new nozzle check valve would solve problem

- Nozzle valves were installed and problem was solved

Ready to try AFT Impulse?

Problem Explained

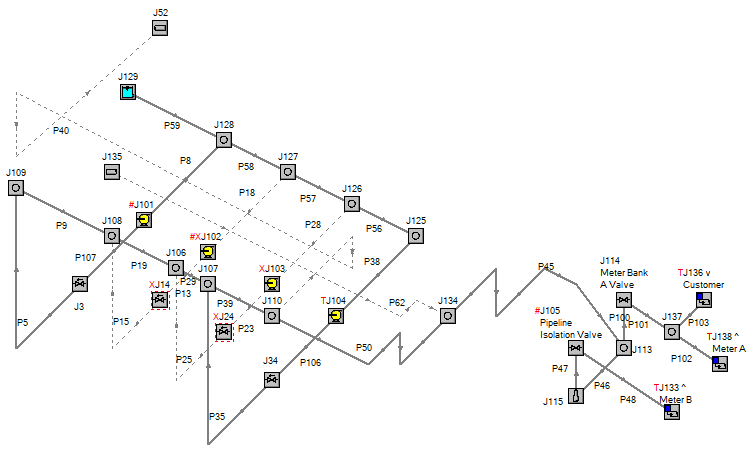

Beta Machinery Analysis (BETA) was asked to investigate a waterhammer and valve slamming problem after pump shutdown in a Canadian crude oil booster pump station that sends product from tanks to a transportation pipeline (see Figure 1).

Jordan Grose, pump systems manager, modeled the system with AFT Impulse and gathered field measurements for model calibration. The initial model results did not match well with the field data since several unknowns existed on the downstream piping past the Pipeline Company meter banks and details of this part of the system were not available. This led to investigations of the model boundary conditions (see Figure 2).

Tools & Analysis

A new approach involved making educated trial and error guesses at what was likely happening at the meter banks during the shutdown sequence. Grose decided that it would be easier to estimate flow rates rather than pressures, therefore the constant flow element within AFT Impulse was used as the system boundary condition.

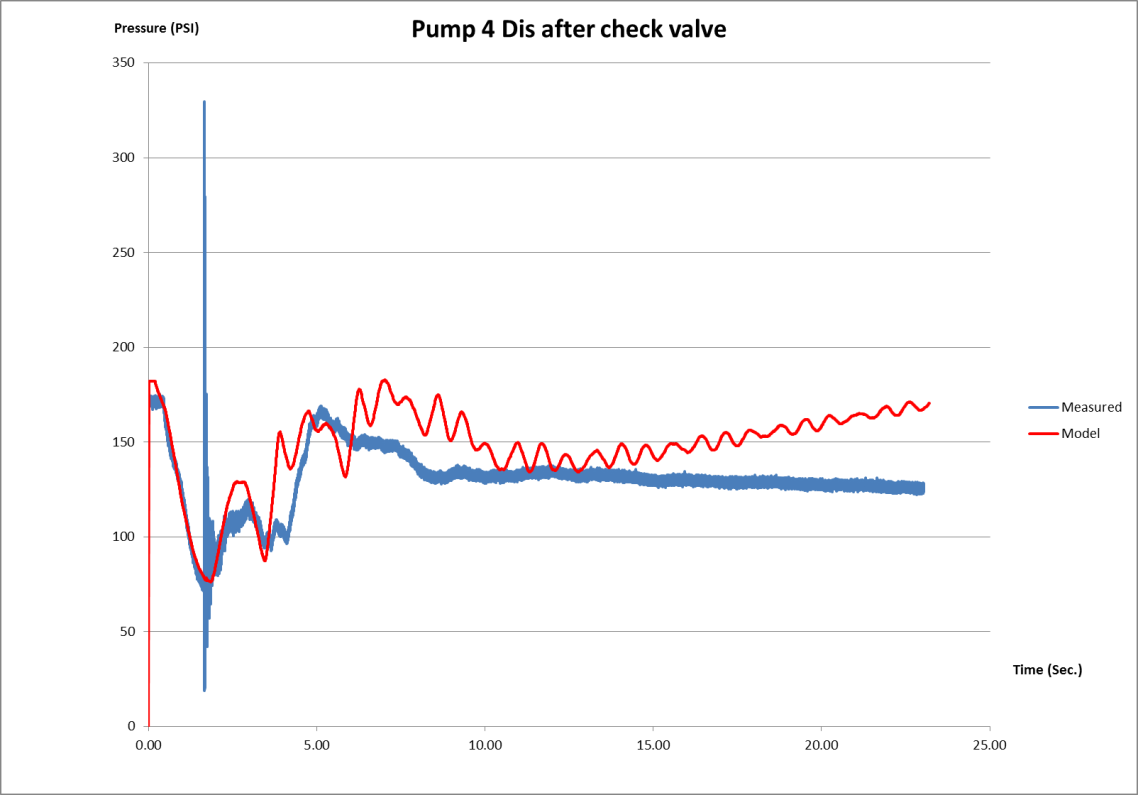

Grose creatively manipulated the AFT Impulse assigned flow junction feature to make the pressures match at the pump discharge check valves. Tweaking of the transient flow profiles and transient trigger settings allowed an iterative approach analysis to occur which eventually led to a very good match of the model predictions with measured field data (see Figure 3).

Solutions & Benefits

In commenting on the benefits of modeling this system with AFT Impulse, Grose said, “AFT software allowed the significant flexibility needed to tweak, by trial and error, boundary condition transients to find and match the field conditions in this complicated system. The software flexibility led to not only a greater understanding of the system, but to a field validated model that was used to solve the client’s significant waterhammer problem.”

Grose continued, “AFT Impulse provided the flexibility to vary the induced transient flow profiles with many transient activation options. Without this functionality, modeling a system with as many important unknowns as this would not have been possible.”