Campus Steam System Redesign Moves Forward After Data Matches AFT Arrow Model

AFT Arrow™ Case Study

Schuyler Engineering | Campus Steam System| General Facility

“The steam pressures recorded were within 5%

of the results of the AFT Arrow analysis.”

-Michael Martino, Project Engineer

PROBLEM

- Downsizing of psychiatric center campus led to reduced steam demand

- Previous study recommended $1M in modifications to accommodate new demand

ANALYSIS

- Both options explored lowering steam pressure for lower demand to confirm recommendations

- AFT Arrow model was verified by comparing to throttled field data

SOLUTION

- Field data matched Arrow predicted data to within 5% in most cases

- Findings of previous study were confirmed and conversion of system could proceed

Ready to try AFT Impulse?

Problem Explained

Michael Martino, project engineer at Schuyler Engineering, was asked to confirm a previous study recommending that the existing medium-pressure steam supply could be converted to a low-pressure system for space heating, domestic hot water, kitchen steam kettles, humidification and sanitizing for the Rockland Psychiatric Center (RPC) in Orangeburg, New York.

Since the recommended modifications would cost more than $1 million, Martino performed a low-pressure throttling test to verify the results of the AFT Arrow model, giving further confidence to the previous study.

Tools and Analysis

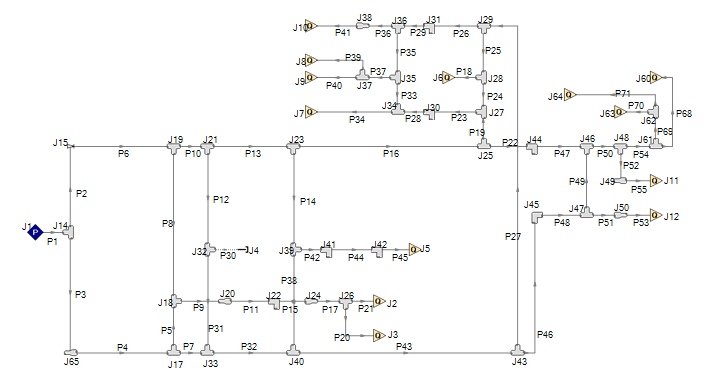

The Central Steam Plant at RPC dates from the late 1920s. At one time the plant supplied steam to nearly 100 buildings of various sizes, construction, use, and occupancy. The buildings were located at various points on more than 240 acres of RPC campus. Since the 1970s the RPC campus has been steadily downsized. More than half of the buildings once supplied from the plant are no longer used or have been demolished.

As the campus consolidates, the operating conditions on the plant and steam distribution system have changed significantly. Although the original system was designed for medium-pressure steam, the reduction in steam demand as the campus consolidated sparked the idea to operate the piping system with low-pressure steam.

Solutions & Benefits

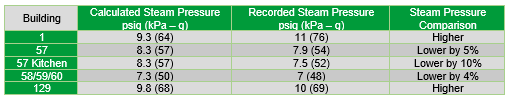

The existing system was throttled to 12 psig (83 kPa-g) and model predictions were compared to pressure measurements at the most distant buildings. The throttling test was performed in January 2013, with an outside temperature of 13°F (-10°C). The steam pressure at the location of the future Central Plant was 11 psig (76 kPa-g).

Test results confirmed the findings of the original low pressure steam study and showed that the steam distribution system can adequately meet the campus heating loads when supplied with steam at 12 psig (83 kPa-g) (see Table 1). The steam pressures recorded were within 5% of the results of the AFT Arrow analysis. Since the analysis closely matches the results of the throttling test, the conversion to low pressure steam is proceeding.