Significant Man-Hours Saved by Transitioning AFT Fathom Model to AFT Impulse to Analyze Surge Transients

AFT Fathom™ Case Study

Fluor | Refinery Cooling Water | Oil & Gas

“Using the seamless transfer from the AFT Fathom steady state

hydraulic model to the AFT Impulse, the manhours spent for the surge

analysis were significantly reduced, resulting in reduced cost and

schedule for this lump-sum project.”

– Loukas Papathanasiou, Process Manager

PROBLEM

- Major facility upgrade changed requirements on cooling system

- Needed to size equipment, calculate temperatures, and evaluate surge to comply with ASME and AWWA standards

ANALYSIS

- AFT Fathom used to model steady-state for sizing and temperatures

- AFT Impulse used to evaluate surge, where transient cavitation was a significant issue

SOLUTION

- Project was completed on budget

- Vacuum breaker/air release valves sized and located

- Bringing Fathom model into Impulse saved significant time

Ready to try AFT Fathom?

Problem Explained

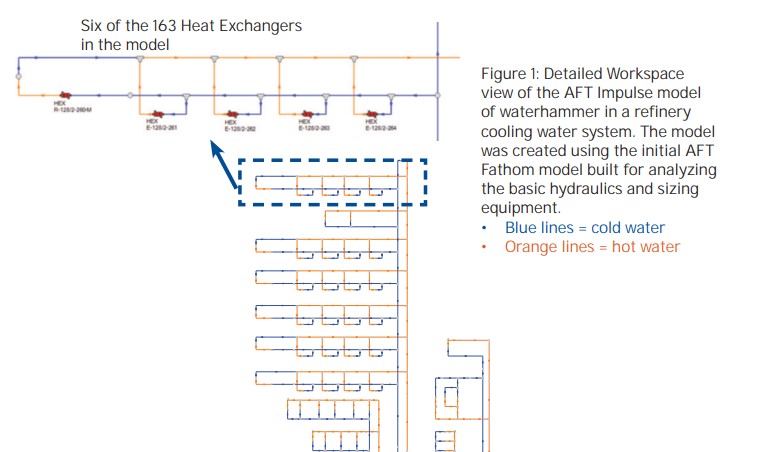

Loukas Papathanasiou, Process Manager for Fluor, utilized AFT Fathom and AFT Impulse to complete the design of a cooling water system and the analysis of that system’s surge transients. Using both software programs together gave him the ability to easily simulate, analyze, and troubleshoot the massive system.

Papathanasiou created a steady-state model in AFT Fathom to simulate the cooling water hydraulics during a major upgrade to a refinery in Kuwait. Part of the Kuwait National Petroleum Company (KNPC) Clean Fuels Project (CFP), the Mina Abdullah Refinery was expanded to refine 454,000 bpd via this multi-billion-dollar project. Fluor designed and constructed the new cooling water system, which circulates 40,300 m3/h (177,000 gpm) of cooling water to the new CFP units.

Tools & Analysis

Papathanasiou used AFT Fathom to size the equipment and to model heat transfer to determine fluid temperatures.

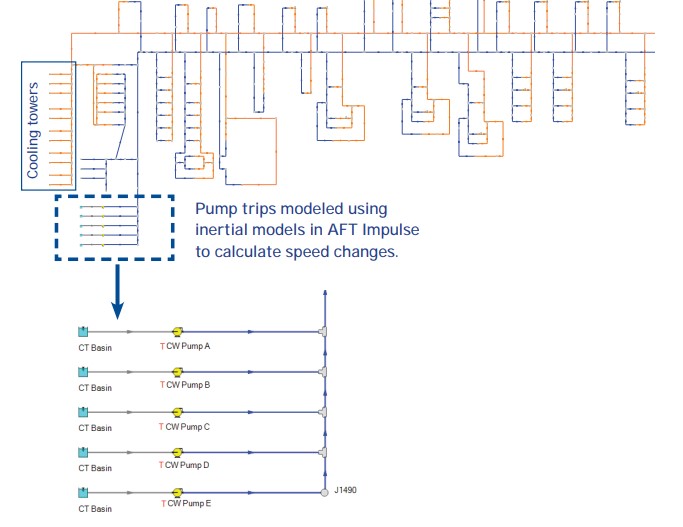

Then the extensive AFT Fathom model was used to generate the AFT Impulse model which performed the surge analysis to ensure technical integrity during transient events, in compliance with the international standards (ASME, AWWA) and the SHELL Design and Engineering Practices (DEP).

The AFT Fathom model made extensive use of the heat exchanger feature to properly size and ensure the capacity of the equipment for the upgrade.

Solutions & Benefits

The AFT Impulse model made use of the discrete gas cavity model (DGCM) to calculate cavitation and vapor formation. This was important for the execution of this study considering extensive vacuum generation and collapse had been occurring in various locations throughout the system.

The dual vacuum break/air release valve feature was important too, as these were used to mitigate the excessive surge pressures by letting in atmospheric air to prevent low vacuum pressures.

Finally, the Scenario Manager contributed in optimum handling of changes and operating cases in the model as it automatically applied the change to all sub-scenarios. The model was created based on thousands of isometrics. “Using the seamless transfer from the AFT Fathom steady state hydraulic model to the AFT Impulse, the manhours spent for the surge analysis were significantly reduced, resulting in reduced cost and schedule for this Lump-Sum project,” said Papathanasiou.