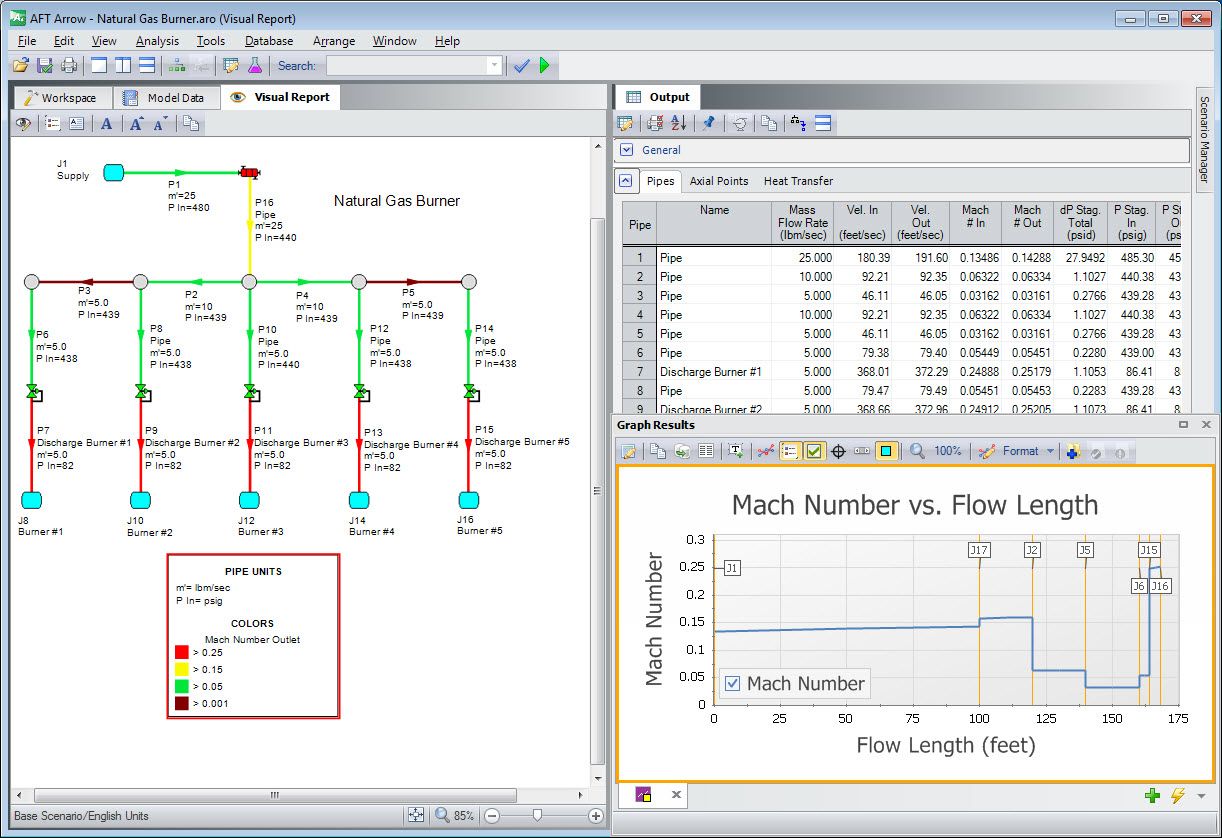

Calculate Compressible Flow

AFT Arrow™ 10

What Is

AFT Arrow

AFT Arrow is a fluid dynamic simulation tool used to calculate pressure drop and flow distribution in gas piping and ducting systems.

- Accurately simulate individual components and their interaction including effects of heat transfer, real gases and choked flow

- Tightly integrate equipment characteristics, analysis and output with your system’s schematic representation

- Utilize a wide array of features without sacrificing your need for a short learning curve

- Compare the performance of new designs and assure all design requirements are met.

- Identify and correct operational problems in installed systems

- Significantly improve the quality of systems engineering and produces less costly, more efficient and more reliable piping systems

How It Works

Modules

Validation Resources

How Does It Work?

AFT Arrow’s powerful solution engine simultaneously solves five fundamental equations; mass, momentum, energy, state and Mach number. AFT Arrow uses a modified Newton-Raphson matrix iteration method plus proprietary methods developed by AFT so you can achieve a true and rigorous compressible flow solution.

Goal Seek and Control

Identifies input parameters that yield desired output values and simulates control functions

Extended Time Simulation

Models dynamic system behavior and how critical system parameters vary over time

Goal And Seek Control

Identifies input parameters that yield desired output values and simulates control functions

Automated Network Sizing

Evaluates the complex interaction of system variables to reveal combinations of cost savings

Case Studies

Technical Papers

Fluids Supported

Designed for fluid systems containing the below fluids and more.

Steam

Compressed Air

Gases

Dust Collection

Modeling & Simulation

Typical Applications

Primary Features

Experimenting With

Operating Conditions And Scenarios

For Design Or Operational Projects

Easily change system input data, including valve positions, pump operation, control set points, pressures, temperatures, and more

Model a wide range of system components for both design and operational cases

Vary your system line-up: open/close pipes and valves, turn pumps on or off, set control valves to fail position

Specify design alerts that automatically highlight output values that are out of range for flow, pressure, velocity, pump efficiency, and more

Find pump data from online manufacturer catalogs

Compile libraries of your frequently used piping components and select them from a drop-down list

Address the viscosity and frictional changes associated with pumping non-settling slurries and a variety of other non-Newtonian fluids

Evaluate codes and industry standards applied in the model

Calculate the cost of system pipes and components as well as energy cost

- Import piping layouts from:

- CAESAR II® Neutral files supported by AutoPIPE®, ROHR2, TRIFLEX®, etc.

PCF Files supported by AutoCAD Plant 3D®, SmartPlant®, CADWorx®, and other GIS shapefiles supported by ArcGis, etc.

Import and export files in EPANET format

Clearly import Excel data into multiple scenarios and export with the Excel Export Manager

Export data to evaluate Flow Induced Vibration (FIV) according to Energy Institute Standards

Typical Applications Of

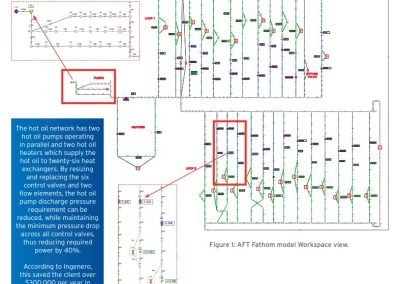

AFT Fathom

- Pipe and Duct Sizing

- Relief valve sizing and system calculations

- Compressor and Fan sizing and Selection

- Control Valve sizing and Selection

- Simulating System operation and component interaction

- Evaluating pipe insulation and heat transfer in pipes and heat exchangers

- Troubleshooting existing systems to determine the cause of operational problems

Primary Features Of

AFT Fathom 12

Track all your design variants and potential operating conditions in a single file with Scenario Manager

Use integrated, customizable graphing and reporting to make analysis visually intuitive

Evaluate Pump and System curve interaction including composite head and efficiency curve

Calculate the capital costs of pipes and components as well as operating energy expenses

Leverage built-in libraries of fluids and fittings to build your own database upon

Consider viscosity and frictional effects from non-Newtonian viscosity models or non-settling slurries

Model your centrifugal and positive displacement pumps to account for

- Shifting performance curves through variable speed control and impeller trimming

- Viscosity corrections using standards from the Hydraulic Institute

- Wire-to-water efficiency including pump, motor and variable frequency drive efficiencies, used to size motors and evaluate power usage

- Acceleration head loss for positive displacement pumps

NPSH evaluation

Size motors and evaluate power usage by considering wire-to-water efficiency (including pump, motor and VFD efficiencies)

Account for heat transfer effects in pipes and heat exchangers

Ensure a design adheres to industry standards such as API 526, ANSI/HI 9.6.3, API 610, or NFPA Standards

Import piping layouts from CAESAR II® Neutral files, PCF Files, and GIS shapefiles regardless of source

Integrate with Excel to import model data and export output data

Built-in libraries of fluids (including NIST REFPROP and ASME Steam Tables) and fittings which can be extended and customized

Optional Chempak add-on utility provides a thermophysical database of almost 700 fluids

Let's Get Started!

Want to learn more about AFT software and see if it's the right solution for you?