AFT Fathom Used to Minimize Pumping Cost for Cooling Water System

AFT Fathom™ Case Study

Universidade Federal de São Paulo (UNIFESP) | Cooling Water | General Facility

“The additional piping cost of an isolated distribution header was

outweighed by reduced pump and energy costs.”

-Dr. Ricardo FF Pontes

PROBLEM

- Research project determining optimal pump number and configuration

- Considered 3 designs:

–Single Pump/Header

–Additional Pump

–Isolated Pump and Header

ANALYSIS

- Modeled system in AFT Fathom to size pumps

- AFT Fathom totaled capital and recurring costs for design alternatives

–Additional sensitivity on system life, interest rate, and energy cost

SOLUTION

- Established methodology to optimize pumps and system configuration for total cost

- Found improved pumping justified additional pipe cost of isolated pump and header

Ready to try AFT Fathom?

Problem Explained

A large part of engineering is evaluating design tradeoffs. For example, in a pumping system, one pump option may be more efficient than others, but that efficiency often comes at larger initial cost. A less capital-intensive pump might be less efficient or have additional maintenance costs to consider. Similarly, system configurations have their own cost tradeoffs to consider.

Designing only for minimum energy use or minimum initial cost is unlikely to find an optimal solution due to these tradeoffs. Instead, minimizing the combined initial capital costs and recurring energy and maintenance costs is essential for optimal pump selection and system configuration.

Tools & Analysis

Dr. Ricardo FF Pontes’ used AFT Fathom on his research to explore pump and system configuration impact on system cost. Pontes’ cooling water loop system had 10 consumers of variable demand. The consumers ranged from 32 to 4,100 m3/hr (141 to 18,050 gpm) in cooling water demand, causing significantly different losses across their control valve elements.

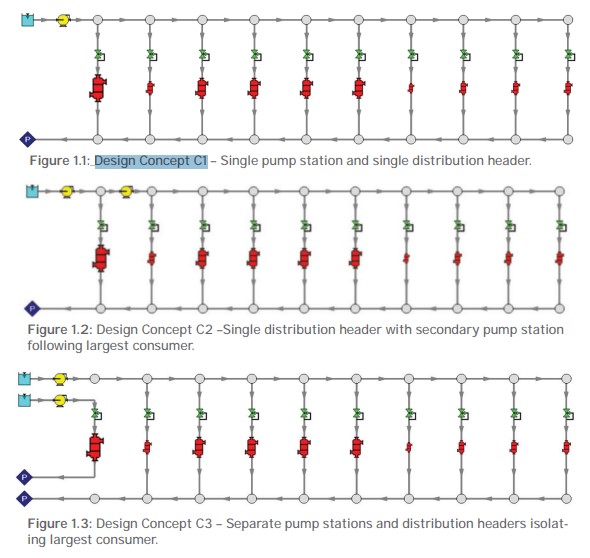

Significant losses across a control valve represent large energy cost, since energy added from a pump is immediately spent through control valve losses. Pontes’ research compared three configuration concepts. These concepts explored a single pump, single-header system (C1), a single-header with additional booster-pump station (C2), and independent pump stations and headers isolating the major consumer (C3).

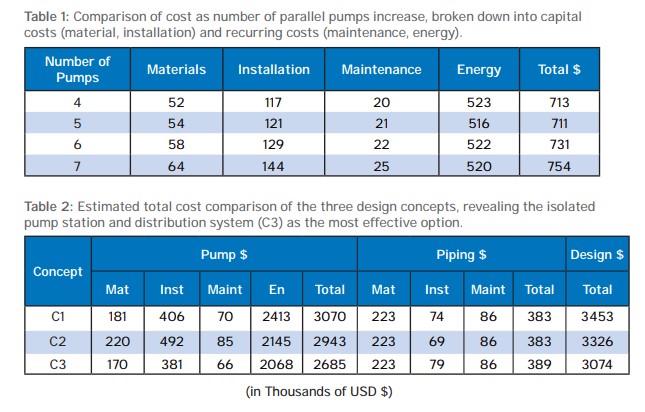

In each concept, Pontes optimized the number of pumps based on total cost, considering the pump’s material, installation, maintenance, and recurring energy cost.

Solutions & Benefits

Pontes found the additional piping cost of an isolated distribution header was outweighed by reduced pump and energy costs. Additional sensitivity analysis on system lifespan, interest rate, energy cost, and order of consumers was performed in AFT Fathom, in all cases confirming the isolated system as optimal. While Pontes’ research and conclusions were specific to this particular system, his approach and methodology can be applied to design other cooling water system alternatives.

With AFT Fathom’s built-in cost capabilities, not only can engineers evaluate the technical requirements of their system, but they can easily manage and evaluate alternatives to optimize for cost and energy. With additional tools like the Automated Network Sizing add-on module, sizing pipes specific to operation can further reduce system cost.