World War II Remnant: Nuclear Waste Transfer Lines Pressure Evaluation using AFT Fathom and AFT Impulse

AFT Fathom™ Case Study

ARES Corporation | Waste Transfer Lines | Nuclear

“The Scenario Manager was used extensively to evaluate and compare

the effects different system parameters had on the maximum

transient pressure of the system. Conclusions were determined

quickly and efficiently.”

– Kodi Dixon, Senior Mechanical Engineer

PROBLEM

- Residual nuclear waste needed to be transported to treatment facility safely

- Insufficient confidence in manufacturer data for nuclear surge analysis

- Potential for siphoning and column separation

ANALYSIS

- An AFT Fathom model was used to compare different system control methods

- AFT Impulse was used to compare the impact of system parameters on surge

SOLUTION

- AFT modeling allowed for worst-case scenario considerations where data was potentially unreliable

- A siphoning solution was implemented based on model results

Ready to try AFT Fathom?

Problem Explained

A one-mile (1.6 km) long piping system needed to be designed to transfer low-level radioactive waste generated during plutonium production for nuclear bombs used in World War II. The weapons production process left 56 million gallons (212 million liters) of solid and liquid radioactive wastes stored underground at Tank Farms facilities. It will be pumped to a Waste Treatment Plant (WTP) and transformed into a stable, glass product.

The goal of ARES Corporation’s evaluation was to determine the sustained and occasional internal pressures in the conceptual Waste Feed Delivery (WFD) system piping from the Tank Farm to the WTP Low Activity Waste (LAW) facility, as well as determine if the pressures were within the allowables of ASME B31.3.

Senior Mechanical Engineer, Kodi Dixon, said the most difficult challenge was due to the difference between the WTP facilities being classified as general service with a 150 psig (10 bar-g) design pressure; and the Tank Farms facility being classified as safety significant with a 400 psig (28 bar-g) design pressure. In addition, the WTP facilities were under construction whereas the Tank Farms were in design.

Tools & Analysis

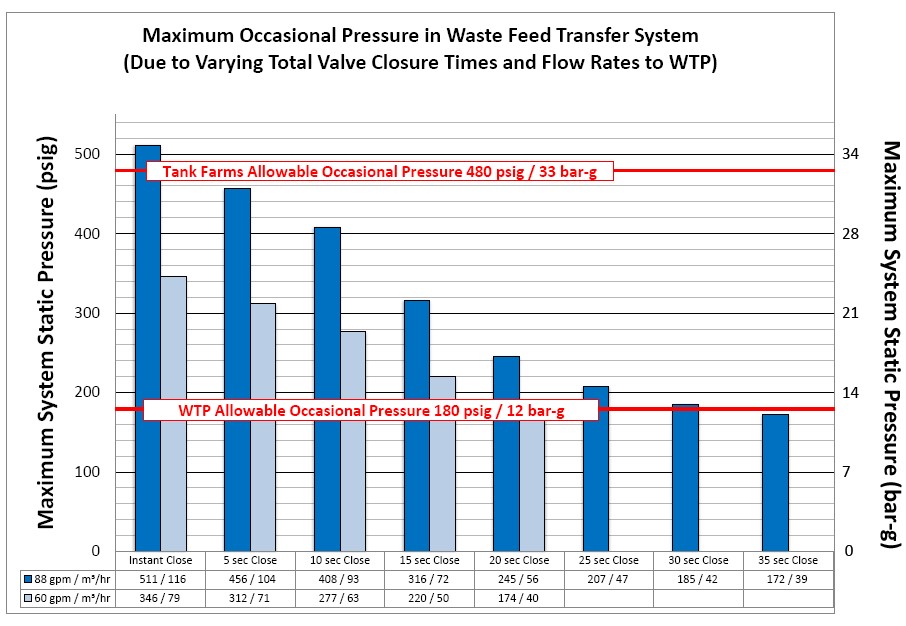

As the valve(s) in the WTP facility were considered part of a general service system, the closure times were based on manufacturer data. However, the Tank Farms valve closure rates could not be based on manufacturer data because they had not undergone nuclear safety and licensing evaluations. Therefore, there was not enough confidence in the valve operation to ensure no failure methods exist, which could result in a faster closure time. Ultimately, this meant the transient evaluations had to consider instantaneous valve closures in a system already susceptible to significant transient pressures with a low design pressure.

Assuming instant valve closure is a conservative, worst-case assumption. To further complicate the evaluation, the potential for column separation and siphoning required the use of an air relief feature to mitigate such conditions – while preventing the release of the nuclear waste, or control and contain if it is released. However, similar to the valve closures, one cannot ensure they will not fail open unless they are analyzed for nuclear safety.

Solutions & Benefits

It was determined to implement passive air relief devices called anti-siphon, or weep holes, into the side of the pump columns within the head space of the waste tanks. Then using the siphoning flow rates determined in the AFT Fathom model, Dixon was able to hand calculate that the anti-siphon holes could sufficiently “break” the flow of siphon and any column separation conditions that would occur do to elevation differences.

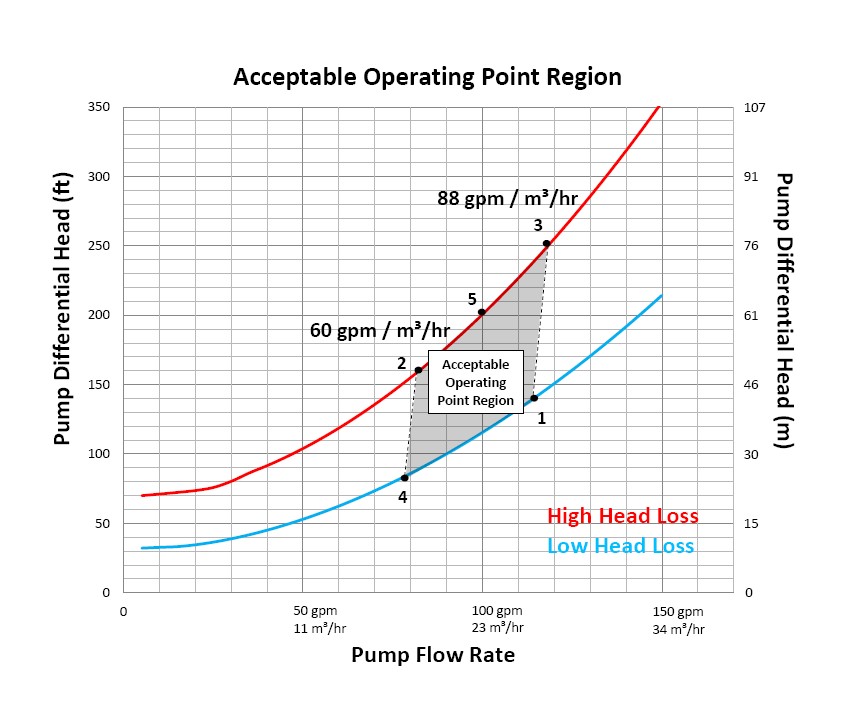

AFT Fathom was also used to help determine the best system control method to size the WFD system pump. The selection of the control method also needed to consider the impact it would have on the transient pressures that would be created in the system during valve closures. Using AFT Fathom, Dixon’s team was able to eliminate the control methods which did not fall within the allowable operating range and focus on the ones that could, while also minimizing pressure transients.

Once the system control method was defined and a pump selected, the actual transient calculations were performed using AFT Impulse.

Extensive valve sensitivity studies were also performed along with pressure profiles to help better understand the pressure transients that were occurring on both the upstream and downstream side of the valve. Without the use of AFT Impulse, the same calculations would have likely never been performed.