AFT Fathom Instrumental in Chrysler Energy Savings Project: Plant Saves $194,000 Per Year

AFT Fathom™ Case Study

Fiat Chrysler Automobiles | Coolant Filter System | Automotive

“[This] was one of the more complex energy optimizations undertaken on

process equipment at Chrysler. We saved over $194K/year in energy and

were awarded a $200K rebate from the local electric utility. I know for a fact

that without AFT Fathom, the project would have never happened.”

PROBLEM

- Reduce energy use in a coolant circulation and filtration system at an engine plant

- Energy use addressed by replacing supply header pressure control with pump speed control

ANALYSIS

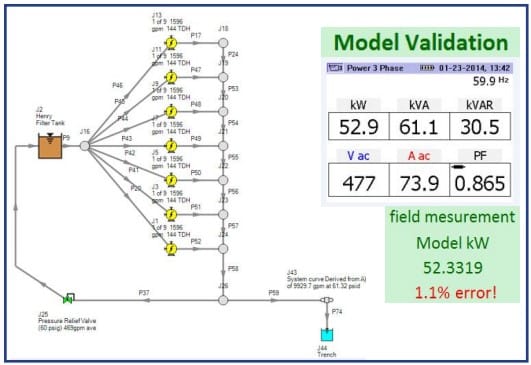

- An AFT Fathom model was built and calibrated to the existing conditions to 1.1% of field measurement

- Thirty scenarios were evaluated over four systems

SOLUTION

- Energy use was reduced by 25%, or about 21% per engine produced

- Adjusting feedback system improved maintenance intervals and pump life as well

Ready to try AFT Fathom?

Problem Explained

Chrysler used AFT Fathom to model four large central coolant filter systems in the Dundee Engine plant located in Dundee, Michigan. Coolant is used in the engine machining process to lubricate the metal cutting process and to carry away chips from the machining centers. The large central coolant filter system consists of a large network of piping, pumps, and filtration machines, and trenches that circulate clean coolant and return coolant and metal chips for separation and filtering (see Figure 2).

The purpose of the project was to reduce energy use by switching from supply header pressure control to pump speed control using remote pressure feedback. The existing cooling system was energy intensive. Chrysler wanted to develop a model that matched existing conditions, and then use that model to predict energy savings for different capital expenditure scenarios. Thirty operating scenarios were evaluated over four systems for the project.

Tools & Analysis

he model, based on conservative assumptions, predicted the savings to be approximately 16%, which was enough to secure capital funding and proceed with the project. After implementation, the actual savings achieved was 25%. Measurement and validation of the energy savings were done using two methods. The first was by collecting power kW readings at each of the pumps before and after project implementation.

Secondly, Chrysler used filter gallery substation level kW for the plant, normalized for production as a secondary means of measurement and validation.that showed reduced energy use by about 21% per engine.

The plant also derived operational benefits. Coolant flow feedback was moved out to the process, ensuring it had precisely the flow required as production volume varies. By slowing the pumps most of the time, maintenance intervals were extended. Pump service life is also extended since the cycles and forces in the pump are reduced, lowering overall lifecycle costs. These benefits were not quantified in this project but they are real.

Additionally, the waste heat due to excessive pumping was eliminated, saving chiller energy and cooling tower water and chemicals.

Solutions & Benefits

When asked about the benefits of using AFT Fathom, Bryan Whitfield, senior energy specialist at Chrysler said, “Up to this point, engineers and the original equipment manufacturers could only speculate, never being able to produce a legitimate engineering model of these systems that could withstand any level of engineering review. With AFT Fathom, we could finally complete the modeling required which allowed us to select the best scenario that met our financial requirements. Secondly, it gave us a way of communicating the ideas in a simple way, making the change more acceptable to the process engineers and finance people.”

This project also won first place in the energy category, Fiat Chrysler Automobiles Environment, Health & Safety Leadership Awards 2015.