AFT Fathom Provides Critical Accuracy at Dupont

AFT Fathom™ Case Study

Dupont Engineering | Absorber System | Chemical & Petrochemical

“We are actively directing our full-service design contractors

to use Fathom on all of our projects”

-Judy Hodgson, a Pump Consultant at Dupont Engineering

PROBLEM

- Experimental chemicals must be combusted for absorption by a caustic solution circulation system

- The circulating pump in this absorber system continually failed due to excessive operating speed

ANALYSIS

- Excessively reducing pump speed could cause inadequate flow

- An AFT Fathom model allowed for comprehensive analysis, considering heat exchanger fouling, pump speed, and liquid level

SOLUTION

- Pump speed was reduced with confidence to maintain the required circulation rate

- Field results after implementation had less than a 0.1% difference from Fathom results

Ready to try AFT Fathom?

Problem Explained

Dupont’s vast capabilities in the development and production of chemicals require extensive underlying resources. Among these are Dupont Engineering who are tasked to support the demands of Dupont’s wide-ranging activities, including a highly developed specialization in the application of pumps. It was this capability that was called upon to solve a recurring problem at Dupont’s Experimental Station.

The Experimental Station is a corporate “university” where new chemicals are developed, and safe disposal of chemicals is essential for operation. Key to this safe disposal is an incinerator where combustion breaks complex compounds down into simpler compounds that are absorbed by a caustic solution circulation system. Critical to the absorber system’s operation was a circulating pump that was continually failing.

Tools & Analysis

Judy Hodgson, a Pump Consultant at Dupont Engineering, was called in to solve the Experimental Station’s problem. Judy determined that the recurring failure of the pump’s rubber lining and bearings was due to excessive operating speed. A reduction in operating speed to solve the pump failures could not, however, be allowed to create another, more serious problem: inadequate flow in the absorber system.

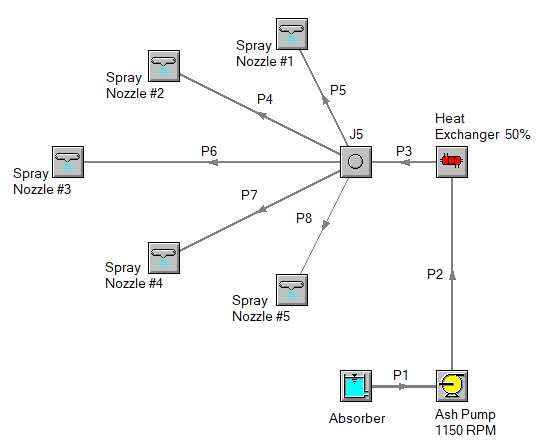

With no historical data available to indicate where the pump was operating, Judy modeled the caustic circulation system’s sump, circulating pump, heat exchanger, spray nozzles and interconnecting piping using AFT Fathom (see Figure 1). Knowing pumps don’t operate just at a design point, Judy performed a comprehensive analysis of the operating envelope, studying the effects of pump speed, heat exchanger fouling and liquid level.

Solutions & Benefits

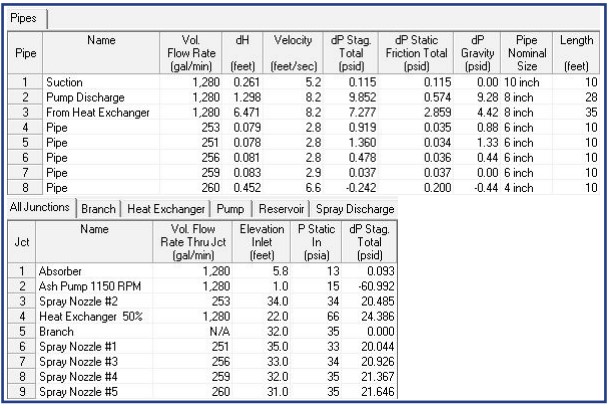

As a result of this analysis, it was concluded that pump speed could be reduced to 1150 RPM, a level commensurate with good service life of the pump lining and bearings, while providing the required circulation rate of 1,280 gpm (see Figure 2). EPA requirements mandated testing to demonstrate the revised pump speed would produce the required flow in the absorber system. Test results were within 1 gpm and 0.1 psi of that predicted by AFT Fathom, less than 0.1% error.

Judy explained that Dupont’s Best Practice for Pump Application Design specifies AFT Fathom for system modeling and analysis; “We are actively directing our full-service design contractors to use Fathom on all of our projects”. Dupont’s standardization on AFT Fathom followed a comprehensive comparison of available pipe flow software, selecting AFT Fathom for the ease of use of its drag & drop interface, Visual Report, extensive output and graphing capabilities and its ability to easily investigate different scenarios. Indeed, all operating scenarios of Dupont’s pumping systems are now analyzed before making decisions on pumps.

Figure 1 – A circulating pump drawing caustic solution from the absorber discharges through a heat exchanger to a distribution hub (J5) to five spray nozzles.

Figure 2 – AFT Fathom output data